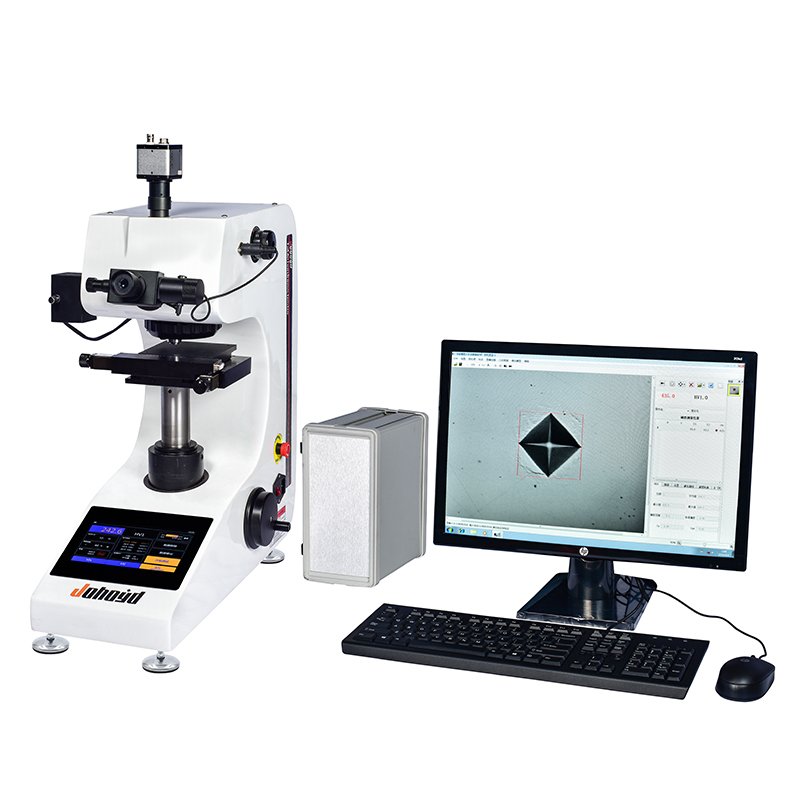

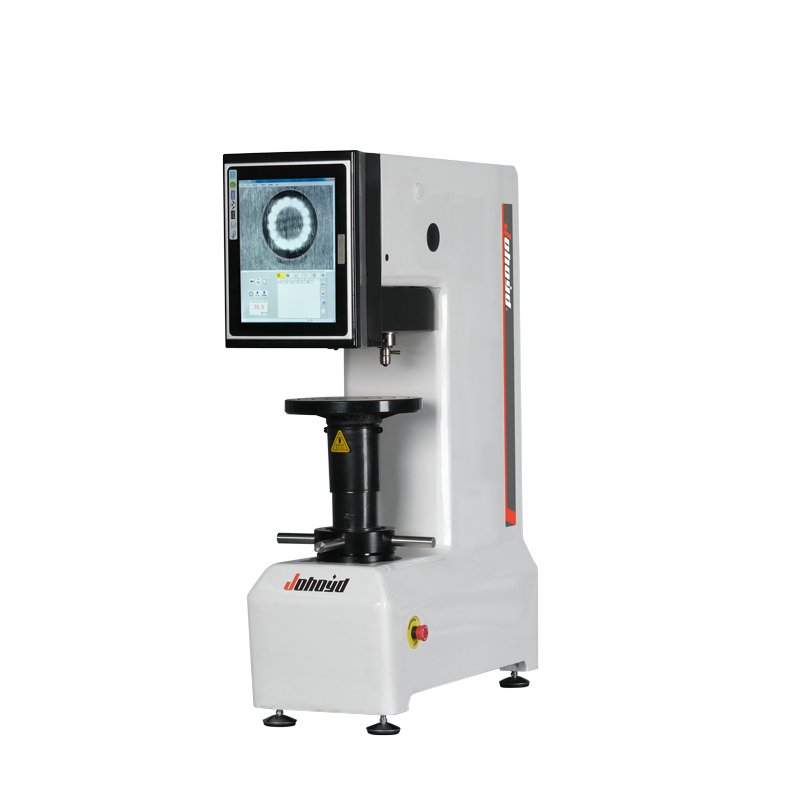

Sensor Touch Screen Digital Display Brinell Hardness Tester (CSHBRV-250F)

As a new generation of automatic hardness tester, the sensor touch screen digital display Brinell hardness tester is a high-tech product integrating optics, machinery and electronics. It adopts a closed-loop loading control system, with high test force accuracy, good repeatability and stability of the indicated value. The shell is cast in one piece, and the surface is treated with automotive paint. It has a novel shape, good reliability, operability and repeatability, and is fully functional with clear and intuitive display. It adopts automatic loading and unloading test force, and can perform three test methods of Brinell, Rockwell and Vickers. It is a multifunctional hardness tester with a thirty-second level measuring scale, which can meet various hardness test needs. The measuring device adopts a grating sensor, and the hardness indication is directly displayed on the LCD screen. It can automatically convert various hardness parameters. When testing a cylinder, it can automatically add a correction amount. It has the characteristics of high test accuracy, simple operation, high sensitivity, easy use, and stable indication. Equipped with a built-in printer, and can be equipped with an RS232 data cable to connect to a computer via a hyperterminal, or export measurement reports to a USB flash drive. The large-screen LCD touch screen display interface has rich display content and is easy to operate.

Main features of the instrument:

- The optical system designed by senior optical engineers not only has clear images, but can also be used as a simple microscope. The brightness is adjustable, the vision is comfortable, and it is not easy to get tired after long-term operation;

- The 8-inch LCD touch screen can intuitively display the hardness value, conversion hardness, test method, test force, brightness, dwell time, number of measurements, statistical data, test time and other test processes;

- The system has a calibration function, and the input error can be manually adjusted to calibrate the instrument;

- When testing the curved surface, it is automatically corrected according to the standard curved surface radius;

- The adjustable brightness range of the optical system: 0-100;

- It can store 100 sets of test data, and the test data can be viewed at any time, and the current data can be deleted or all test data can be cleared;

- The test force unit can be manually selected to convert to each other, and the conversion unit is: (Kgf, N)

- It can simultaneously display: maximum value, minimum value, average value, number of tests, test block name (test block number can be entered);

- The main interface can display 4 conversion scales at the same time, and can switch between: national standard (GB), American standard (ASTM) and international (ISO) standards, a total of 21 measurement scales can be converted: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HK, HBW, HS, HBS, HV, Rm (tensile strength), MPa (pressure);

- With diagonal length memory function, the diagonal length is automatically memorized after shutdown, and can be measured directly after startup without secondary zeroing.

- The upper and lower limits of the measurement range can be set and displayed on the main measurement interface. Unqualified valueswill automatically prompt an alarm;

- The operating system has 13 languages, which can be switched at will: Chinese, English, Russian, German, French, Spanish, Portuguese, Turkish, Czech, Japanese, Korean, Thai, and Vietnamese;

- It has three test methods: Brinell, Rockwell, and Vickers, and thirteen levels of test force, which can meet various hardness test requirements;

- It is equipped with a built-in printer, and the test data can also be exported to a USB flash drive for storage and analysis via USB;

- The one-time molding structure of the casting shell is stable and does not deform. The pure white car paint is of high grade and has strong scratch resistance. It is still bright as new after years of use;

- Our company has the ability to independently develop, design, produce and process. Our machines provide lifetime parts replacement and maintenance upgrade services;

Main uses and scope of use of the instrument:

- Determine the Brinell, Vickers, and Rockwell hardness of ferrous metals, non-ferrous metals and cemented carbides:

- Brinell hardness of castings, annealed steel, normalized steel, nonferrous metals and soft alloys;

- Rockwell hardness of heat-treated materials such as quenching and tempering;

- Vickers hardness of nitrided layers, ceramics, thin plates, metal sheets, electroplated layers, and tiny parts;

Detailed parameters of the instrument:

| Product model | CSHBRV-250F |

| Brown scale | HB1/30, HB2.5/31.25, HB2.5/62.5, HB2.5/187.5, HB5/62.5, HB10/100, HB5/250 |

| Rockwell scale | HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRR, HRS, HRV, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, |

| Vickers scale | HV5, HV10, HV20, HV30, HV100 |

| Test force | Rockwell test force: 15, 30, 45, 60, 100, 150Kgf |

| Brinell test force: 30, 31.25, 62.5, 100, 187.5, 250Kgf | |

| Vickers test force: 5, 10, 20, 30, 100Kgf | |

| Product model | Brinell: 37.5×, Vickers: 75× |

| Calibration (calibration) | The machine can be calibrated using standard hardness blocks |

| Maximum test piece height | Rockwell 260mm Vickers Brinell 210mm |

| Indenter-outer wall distance | 165mm |

| Hardness test range | Rockwell: 20-88HRA, 20-100HRB, 20-70HRC Brinell: 5-650HBW Vickers: 10-3000HV |

| Hardness reading | Automatic calculation |

| Power supply | AC220+5%, 50~60Hz |

| Dimensions (mm) | 550×200×720mm |

| Main unit weight | About 85kg |

Standard configuration of the instrument:

| Name | Quantity | Name | Quantity |

| Digital display eyepiece | 1 piece | Objective lens 2.5X, 5X | 1 each |

| Vickers lighting lamp | 1 piece | Brinell lighting lamp | 1 |

| Rockwell 1/16” steel ball indenter | 1 piece | Rockwell diamond indenter | 1 |

| Brinell 2.5mm indenter | 1 piece | Brinell 5mm indenter | 1 |

| Vickers diamond indenter | 1 piece | Standard Rockwell hardness block | 3 pieces |

| Standard Brinell hardness block | 1 piece | Standard Vickers hardness block | 1 piece |

| Medium and V-type test bench | 1 piece | Sliding test table | 1 piece |

| Power cord | 1 piece | Dust cover | 1 |

Be the first to review “Sensor Touch Screen Digital Display Brinell Hardness Tester (CSHBRV-250F)” Cancel reply

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Reviews

There are no reviews yet.