Production Line Quality Control Complete Guide Proven Strategies for Zero-Defect Manufacturing

Outline for the Article on Production Line Quality Control

| Topic Area | Detailed Coverage with LSI Keywords |

|---|---|

| Introduction to Production Line Quality Control | manufacturing quality control |

| Definition of Production Line Quality Control | in-process quality inspection |

| Role of Quality Control in Manufacturing | defect prevention |

| Importance of Production Line Quality Control | consistent product quality |

| Evolution of Quality Control Systems | traditional to smart QC |

| Basic Principles of Production Line Quality Control | process monitoring |

| Difference Between Inline and Offline Quality Control | inspection methods |

| Types of Quality Control on Production Lines | visual, dimensional, mechanical |

| Inline Quality Control Systems | real-time inspection |

| Automated Quality Control Systems | industrial automation |

| Manual Quality Control Processes | operator inspection |

| Statistical Process Control on Production Lines | SPC analysis |

| Key Quality Parameters Monitored | tolerance and performance |

| Quality Control Equipment Used | sensors and testers |

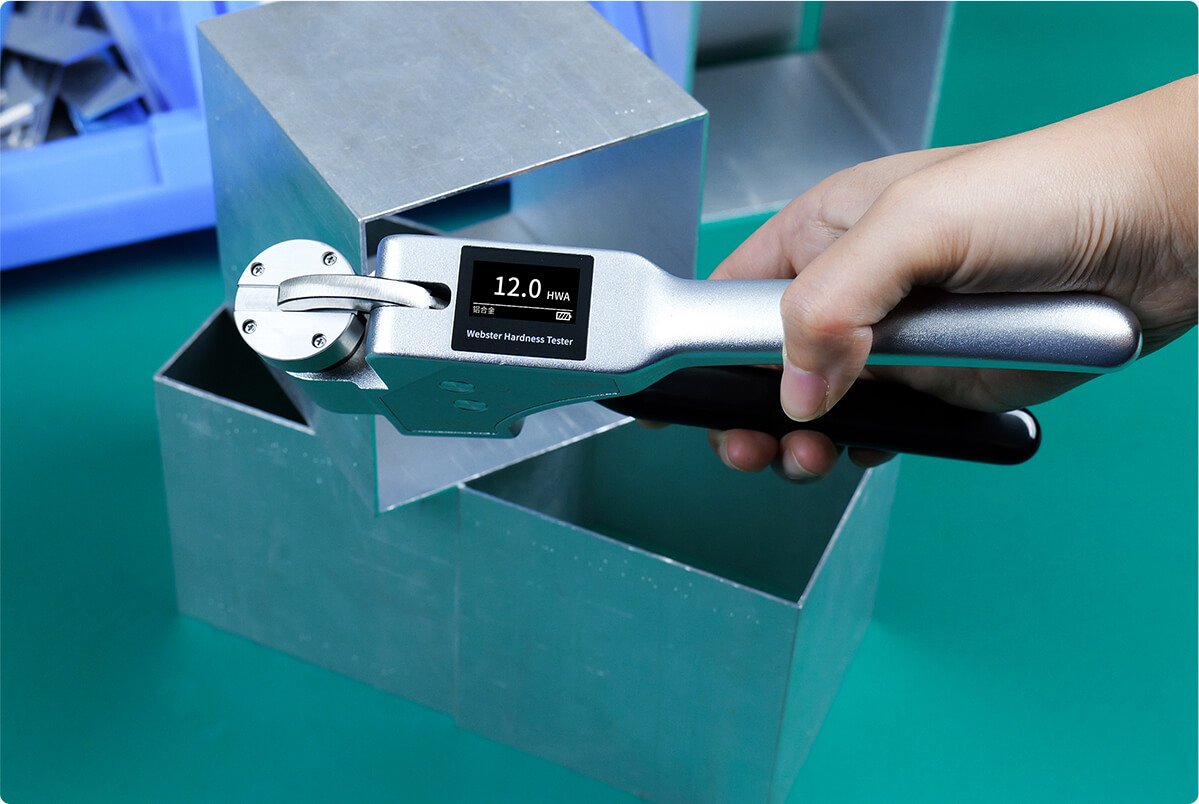

| Role of Hardness Testing in Production Lines | mechanical property control |

| Role of Dimensional Inspection | size accuracy |

| Role of Visual Inspection Systems | surface defect detection |

| Integration of Testing Equipment into Production Lines | system integration |

| Data Collection and Analysis | quality data management |

| Real-Time Feedback and Process Adjustment | closed-loop control |

| Sample Handling and Workflow Design | efficient inspection |

| Cycle Time and Throughput Considerations | production efficiency |

| Accuracy and Repeatability in Quality Control | process stability |

| Calibration of Production Line QC Equipment | traceability |

| Quality Standards and Compliance | ISO, ASTM |

| Quality Control for Metal Manufacturing | steel and aluminum |

| Quality Control for Automotive Production Lines | safety components |

| Quality Control for Aerospace Manufacturing | strict compliance |

| Quality Control for Electronics Production | precision assembly |

| Quality Control in Mass Production | high-volume inspection |

| Quality Control in Custom Manufacturing | flexible inspection |

| Advantages of Production Line Quality Control | defect reduction |

| Limitations and Challenges | system complexity |

| Digital Quality Control and Industry 4.0 | smart factories |

| Quality Reporting and Documentation | traceability |

| Common Quality Control Errors | prevention strategies |

| Selecting the Right Production Line QC System | system selection |

| Maintenance and Reliability of QC Systems | uptime management |

| Safety in Production Line Quality Control | operator protection |

| Brand Expertise and Solutions | Johoyd quality control solutions |

| Future Trends in Production Line Quality Control | AI inspection |

| FAQs | common questions |

| Conclusion | summary |

Introduction

Production line quality control is the backbone of modern manufacturing, ensuring that every product leaving the factory meets defined quality standards. Rather than relying solely on final inspection, production line quality control focuses on monitoring and controlling quality during each stage of production.

In highly competitive industries, effective quality control on the production line is essential for reducing defects, improving efficiency, and maintaining customer trust.

Production Line Quality Control

Production line quality control refers to systematic inspection, testing, and monitoring activities integrated directly into manufacturing processes. These activities detect deviations early and prevent defective products from progressing further down the line.

This proactive approach transforms quality from a final checkpoint into a continuous process.

Definition of Production Line Quality Control

Production line quality control is the practice of ensuring product quality through continuous or periodic inspection and testing during the manufacturing process, rather than only after production is complete.

It emphasizes prevention over correction.

Role of Quality Control in Manufacturing

Quality control ensures that materials, processes, and finished products meet specifications. On the production line, quality control helps maintain process stability and product consistency.

It directly impacts cost, safety, and reputation.

Importance of Production Line Quality Control

Production line quality control is important because it identifies problems immediately. Early detection reduces scrap, rework, and downtime.

Consistent quality improves customer satisfaction.

Evolution of Quality Control Systems

Quality control evolved from manual inspection to automated, data-driven systems. Advances in sensors, software, and automation transformed quality control into a real-time function.

Modern systems support smart manufacturing.

Basic Principles of Production Line Quality Control

The core principles include consistency, traceability, accuracy, and continuous improvement. Monitoring key parameters ensures stable production.

Control replaces guesswork.

Difference Between Inline and Offline Quality Control

Inline quality control occurs directly on the production line, while offline quality control involves testing samples away from production. Inline control provides immediate feedback.

Offline control supports detailed analysis.

Types of Quality Control on Production Lines

Production lines use various quality control methods, including visual inspection, dimensional measurement, and mechanical testing.

Multiple methods ensure comprehensive coverage.

Inline Quality Control Systems

Inline quality control systems inspect parts in real time. They are integrated into conveyors or robotic cells.

These systems support continuous monitoring.

Automated Quality Control Systems

Automated systems reduce reliance on human inspection. Sensors, cameras, and testing devices perform consistent checks.

Automation improves repeatability.

Manual Quality Control Processes

Manual inspection remains useful for complex judgments. Skilled operators identify defects that automation may miss.

Human expertise complements technology.

Statistical Process Control on Production Lines

Statistical process control uses data analysis to monitor process variation. Control charts identify trends and deviations.

SPC supports proactive control.

Key Quality Parameters Monitored

Parameters include dimensions, surface quality, hardness, strength, and appearance. Monitoring critical parameters ensures product performance.

Selection depends on application.

Quality Control Equipment Used

Common equipment includes hardness testers, dimensional gauges, vision systems, and sensors. Equipment selection affects accuracy.

Proper tools ensure reliable results.

Role of Hardness Testing in Production Lines

Hardness testing verifies material properties during production. Inline or automatic hardness testers detect heat treatment issues early.

Hardness control supports safety.

Role of Dimensional Inspection

Dimensional inspection ensures parts meet size and tolerance requirements. Automated gauges and coordinate measuring systems are commonly used.

Accuracy prevents assembly issues.

Role of Visual Inspection Systems

Vision systems detect surface defects such as cracks, scratches, and discoloration. Cameras and AI algorithms improve detection.

Visual inspection protects appearance quality.

Integration of Testing Equipment into Production Lines

Successful integration requires synchronization with production flow. Testing equipment must match cycle times.

Integration minimizes disruption.

Data Collection and Analysis

Production line quality control generates large volumes of data. Analysis identifies trends, root causes, and improvement opportunities.

Data-driven decisions improve outcomes.

Real-Time Feedback and Process Adjustment

Real-time quality data enables immediate process adjustments. Closed-loop control systems automatically correct deviations.

This prevents defect propagation.

Sample Handling and Workflow Design

Efficient sample handling ensures accurate testing without slowing production. Robotic handling improves consistency.

Workflow design affects efficiency.

Cycle Time and Throughput Considerations

Quality control must not become a bottleneck. Modern systems perform inspections within seconds.

Speed supports productivity.

Accuracy and Repeatability in Quality Control

Accuracy ensures measurements reflect true values, while repeatability ensures consistency. Automation enhances both.

Reliable data builds confidence.

Calibration of Production Line QC Equipment

Regular calibration ensures traceable and compliant results. Reference standards support accuracy.

Calibration is essential.

Quality Standards and Compliance

Production line quality control follows standards such as ISO and ASTM. Compliance ensures global acceptance.

Standards guide procedures.

Quality Control for Metal Manufacturing

Metal manufacturing relies on hardness testing, dimensional inspection, and surface analysis. Inline control improves yield.

Consistency is critical.

Quality Control for Automotive Production Lines

Automotive production requires strict quality control for safety-critical components. Inline inspection supports mass production.

Reliability protects users.

Quality Control for Aerospace Manufacturing

Aerospace standards demand rigorous quality control. Production line inspection ensures traceability and compliance.

Precision is mandatory.

Quality Control for Electronics Production

Electronics manufacturing requires precise inspection of small components. Vision systems and functional testing are common.

Accuracy ensures performance.

Quality Control in Mass Production

Mass production benefits from automated, inline quality control systems. High-speed inspection maintains consistency.

Scalability is essential.

Quality Control in Custom Manufacturing

Custom manufacturing requires flexible quality control processes. Manual inspection and adaptable systems are important.

Flexibility supports customization.

Advantages of Production Line Quality Control

Key advantages include:

- Early defect detection

- Reduced scrap and rework

- Improved efficiency

- Consistent product quality

These benefits support competitiveness.

Limitations and Challenges

Challenges include system integration complexity and initial investment. Skilled personnel are required.

Planning reduces risk.

Digital Quality Control and Industry 4.0

Digital quality control integrates data, automation, and analytics. Industry 4.0 platforms enable predictive quality.

Connectivity drives intelligence.

Quality Reporting and Documentation

Digital reporting ensures traceability and supports audits. Automated documentation saves time.

Transparency builds trust.

Common Quality Control Errors

Errors include incorrect calibration, poor integration, and inadequate training. Standard procedures reduce mistakes.

Continuous improvement is key.

Selecting the Right Production Line QC System

Selection depends on product type, production volume, and quality requirements. Expert guidance ensures optimal solutions.

The right system adds value.

Maintenance and Reliability of QC Systems

Routine maintenance ensures uptime and accuracy. Preventive maintenance minimizes downtime.

Reliability supports production continuity.

Safety in Production Line Quality Control

Automated quality control systems improve safety by reducing manual handling. Safety interlocks protect operators.

Safety enhances productivity.

Brand Expertise and Solutions

Effective production line quality control requires reliable testing technology and integration expertise. Johoyd, through https://hardnesstests.com, provides advanced hardness testing and quality control solutions designed for seamless production line integration, helping manufacturers achieve consistent quality and real-time process control.

Future Trends in Production Line Quality Control

Future trends include AI-driven inspection, predictive analytics, and deeper integration with digital twins. Quality control will become increasingly intelligent and autonomous.

Frequently Asked Questions

What is production line quality control?

It ensures product quality during manufacturing.

Why is inline quality control important?

It detects defects immediately.

Which industries use production line quality control?

Automotive, aerospace, electronics, and metal manufacturing.

Does quality control slow production?

Modern systems are designed for high speed.

Is automation necessary for quality control?

Automation improves consistency and efficiency.

How often should QC equipment be calibrated?

According to standards and usage.

Conclusion

Production line quality control is essential for achieving consistent quality, high efficiency, and customer satisfaction in modern manufacturing. By integrating inspection and testing directly into production processes, manufacturers can prevent defects rather than react to them.

With professional solutions from Johoyd available at hardnesstests.com, companies can implement production line quality control systems that deliver accuracy, reliability, and real-time insight. As manufacturing continues to evolve, production line quality control will remain a cornerstone of industrial excellence.

Suggested Internal Links

- Inline Hardness Testing

- Automatic Hardness Tester

Suggested Outbound Links

- ISO Quality Management Standards

- ASTM Manufacturing Quality Standards