Hardness Tester Calibration Service Guide 28 Essential Insights for Accurate Testing

Outline for the Article on Hardness Tester Calibration Service

| Topic Area | Detailed Coverage with LSI Keywords |

|---|---|

| Introduction to Hardness Tester Calibration Service | calibration importance |

| What Is Hardness Tester Calibration | measurement accuracy |

| Why Calibration Is Critical for Hardness Testers | testing reliability |

| Consequences of Poor Calibration | inaccurate results |

| Hardness Tester Calibration Service Explained | professional calibration |

| Types of Hardness Testers Requiring Calibration | Rockwell, Brinell, Vickers |

| Calibration of Rockwell Hardness Testers | depth measurement |

| Calibration of Brinell Hardness Testers | load and indenter checks |

| Calibration of Vickers Hardness Testers | optical accuracy |

| Calibration of Digital Hardness Testers | electronic systems |

| Calibration of Portable Hardness Testers | field calibration |

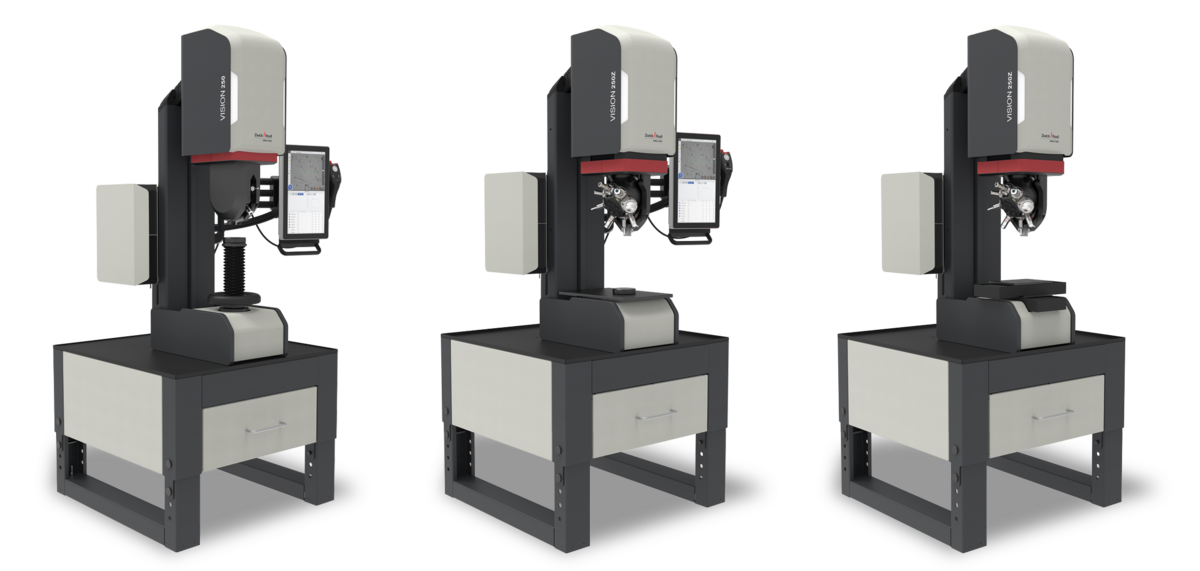

| Calibration of Automatic Hardness Testers | system validation |

| Calibration Standards and Regulations | ASTM, ISO |

| Calibration Intervals and Frequency | maintenance planning |

| Calibration Methods and Procedures | step-by-step process |

| Reference Test Blocks in Calibration | traceability |

| Load Verification During Calibration | force accuracy |

| Indenter Inspection and Verification | wear detection |

| Optical System Calibration | measurement precision |

| Software Verification and Updates | digital accuracy |

| Environmental Conditions for Calibration | temperature control |

| On-Site Calibration Service | customer convenience |

| Laboratory Calibration Service | controlled accuracy |

| In-House vs Third-Party Calibration | cost comparison |

| Calibration Certificates Explained | documentation |

| Traceability and Accreditation | ISO compliance |

| Calibration for Quality Management Systems | ISO 9001 |

| Calibration Service for Manufacturing | production reliability |

| Calibration Service for Laboratories | research accuracy |

| Common Calibration Errors to Avoid | best practices |

| Choosing a Calibration Service Provider | selection guide |

| Johoyd Hardness Tester Calibration Service | brand expertise |

| Cost of Hardness Tester Calibration Service | budgeting |

| Benefits of Regular Calibration | long-term value |

| Future Trends in Calibration Services | digital tracking |

| FAQs | common questions |

| Conclusion | summary |

Introduction

A reliable hardness tester calibration service is the foundation of accurate and repeatable hardness testing. Even the most advanced hardness testing machine can produce misleading results if it is not properly calibrated. Over time, mechanical wear, environmental conditions, and daily use can cause deviations that compromise measurement accuracy.

Calibration services ensure that hardness testers continue to meet international standards, deliver consistent results, and support quality assurance systems across manufacturing, laboratories, and inspection facilities. This article provides a complete overview of hardness tester calibration services, including methods, standards, benefits, and how to choose the right provider.

Hardness Tester Calibration Service

A hardness tester calibration service verifies and adjusts a hardness testing machine to ensure accurate and traceable measurements.

Accuracy begins with calibration.

What Is Hardness Tester Calibration

Calibration is the process of comparing a hardness tester’s measurements against certified reference standards and adjusting the system if deviations are detected.

Comparison ensures correctness.

Why Calibration Is Critical for Hardness Testers

Hardness testing directly influences material acceptance, product safety, and compliance. Calibration ensures that hardness values reflect true material properties.

Trust depends on accuracy.

Consequences of Poor Calibration

Uncalibrated hardness testers can lead to rejected batches, safety risks, and regulatory non-compliance.

Errors multiply quickly.

Hardness Tester Calibration Service Explained

A professional calibration service evaluates load accuracy, indenter condition, measurement systems, and overall performance of the hardness tester.

Comprehensive checks ensure reliability.

Types of Hardness Testers Requiring Calibration

All hardness testers require calibration, including Rockwell, Brinell, Vickers, Shore, microhardness, portable, digital, and automatic systems.

No tester is exempt.

Calibration of Rockwell Hardness Testers

Rockwell calibration focuses on load application accuracy and depth measurement precision.

Depth defines results.

Calibration of Brinell Hardness Testers

Brinell calibration verifies applied force, ball indenter diameter, and indentation measurement accuracy.

Large loads require precision.

Calibration of Vickers Hardness Testers

Vickers calibration emphasizes optical system accuracy and load consistency.

Microscopic precision matters.

Calibration of Digital Hardness Testers

Digital hardness testers require both mechanical and electronic calibration.

Hardware and software must align.

Calibration of Portable Hardness Testers

Portable hardness testers need calibration to maintain accuracy under varying field conditions.

Mobility increases calibration importance.

Calibration of Automatic Hardness Testers

Automatic systems require full system validation, including sensors, motors, and software.

Automation amplifies accuracy needs.

Calibration Standards and Regulations

Hardness tester calibration follows ASTM and ISO standards to ensure global acceptance.

Standards protect credibility.

Calibration Intervals and Frequency

Most hardness testers require calibration annually or after significant maintenance.

Regular checks prevent drift.

Calibration Methods and Procedures

Calibration includes load verification, indenter inspection, reference block testing, and measurement analysis.

Methodical steps ensure confidence.

Reference Test Blocks in Calibration

Certified hardness test blocks provide traceability to national and international standards.

Traceability ensures compliance.

Load Verification During Calibration

Accurate force application is verified using calibrated load cells or force measurement systems.

Force accuracy drives hardness values.

Indenter Inspection and Verification

Worn or damaged indenters can distort results and must be inspected during calibration.

Small defects cause large errors.

Optical System Calibration

Optical calibration ensures accurate indentation measurement, especially for Vickers and Knoop testers.

Clear optics mean correct readings.

Software Verification and Updates

Calibration includes software checks to ensure correct algorithms and data processing.

Digital integrity is essential.

Environmental Conditions for Calibration

Temperature, vibration, and cleanliness affect calibration accuracy.

Controlled environments improve results.

On-Site Calibration Service

On-site calibration minimizes downtime and keeps equipment in production areas.

Convenience supports efficiency.

Laboratory Calibration Service

Laboratory calibration offers controlled conditions for the highest accuracy.

Precision benefits critical testing.

In-House vs Third-Party Calibration

Third-party calibration services provide independent verification and accreditation.

Independence builds trust.

Calibration Certificates Explained

Calibration certificates document results, traceability, and compliance status.

Documentation supports audits.

Traceability and Accreditation

Accredited calibration services provide traceability to recognized standards.

Traceability ensures acceptance.

Calibration for Quality Management Systems

Calibration supports ISO 9001, ISO 17025, and other quality systems.

Compliance strengthens operations.

Calibration Service for Manufacturing

Manufacturers rely on calibration to maintain consistent product quality.

Consistency drives reputation.

Calibration Service for Laboratories

Laboratories require precise calibration to support research and development.

Accuracy enables discovery.

Common Calibration Errors to Avoid

Skipping calibration intervals or using uncertified test blocks leads to unreliable results.

Shortcuts reduce accuracy.

Choosing a Calibration Service Provider

Choose providers with accreditation, experience, and hardness testing expertise.

Expertise matters.

Johoyd Hardness Tester Calibration Service

A professional hardness tester calibration service ensures long-term accuracy and compliance. Johoyd, through https://hardnesstests.com, provides reliable calibration services for Rockwell, Brinell, Vickers, digital, portable, and automatic hardness testers. With certified reference blocks, experienced technicians, and full documentation, Johoyd supports manufacturing, laboratories, and quality control teams worldwide.

Cost of Hardness Tester Calibration Service

Calibration costs depend on tester type, location, and service scope.

Value outweighs expense.

Benefits of Regular Calibration

Regular calibration improves accuracy, reduces risk, and extends equipment lifespan.

Prevention saves cost.

Future Trends in Calibration Services

Digital records, remote monitoring, and automated calibration tracking are shaping the future.

Technology improves control.

Frequently Asked Questions

What is a hardness tester calibration service?

It verifies and adjusts hardness testers for accuracy.

How often should hardness testers be calibrated?

Typically once per year or as required.

Is calibration mandatory for quality systems?

Yes, for most ISO-based systems.

Can calibration be done on-site?

Yes, many services offer on-site calibration.

What standards apply to calibration?

ASTM and ISO standards are commonly used.

Does calibration include documentation?

Yes, certificates are provided.

Conclusion

A reliable hardness tester calibration service is essential for accurate measurements, regulatory compliance, and confident decision-making. Calibration protects product quality, ensures consistency, and supports quality management systems across industries.

With professional calibration services from Johoyd available at hardnesstests.com, organizations can maintain the accuracy and reliability of their hardness testing equipment while meeting international standards. Regular calibration is not just a requirement—it is an investment in trust and performance.

Suggested Internal Links

- Hardness Testing Machine

- Hardness Tester Buyer’s Guide

Suggested Outbound Links

- ASTM Hardness Testing Standards

- ISO Calibration and Measurement Guidelines