Hardness Testing for Automotive Industry Essential Guide Critical Applications for Quality and Safety

Outline for the Article on Hardness Testing for Automotive Industry

| Topic Area | Detailed Coverage with LSI Keywords |

|---|---|

| Introduction to Hardness Testing for Automotive Industry | automotive material testing |

| Definition of Hardness Testing in Automotive | hardness measurement |

| Role of Hardness Testing in Automotive Manufacturing | quality assurance |

| Importance of Hardness Control in Vehicles | safety and durability |

| Evolution of Hardness Testing in Automotive Industry | manual to automated |

| Common Materials Used in Automotive Industry | steel, aluminum, alloys |

| Automotive Components Requiring Hardness Testing | gears, shafts, bearings |

| Hardness Testing Standards for Automotive | ASTM, ISO |

| Rockwell Hardness Testing in Automotive | production testing |

| Brinell Hardness Testing for Automotive Parts | cast components |

| Vickers Hardness Testing for Automotive | precision testing |

| Microhardness Testing in Automotive | surface layers |

| Portable Hardness Testing for Automotive | field inspection |

| Inline Hardness Testing in Automotive Production | real-time control |

| Non-Destructive Hardness Testing | component integrity |

| Hardness Testing for Heat-Treated Automotive Parts | process verification |

| Hardness Testing for Welded Automotive Components | weld quality |

| Hardness Testing for Engine Components | wear resistance |

| Hardness Testing for Transmission Parts | load-bearing strength |

| Hardness Testing for Chassis and Suspension | structural safety |

| Hardness Testing for Automotive Fasteners | reliability |

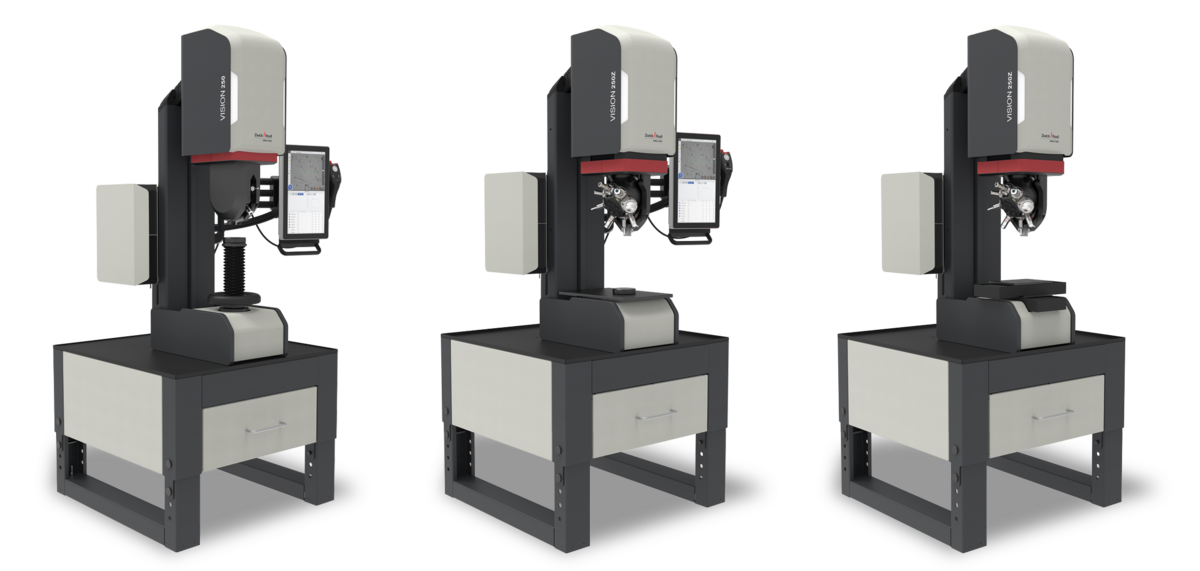

| Automation in Automotive Hardness Testing | high throughput |

| Digital Hardness Testers in Automotive | data accuracy |

| Data Management and Traceability | quality documentation |

| Calibration and Accuracy in Automotive Testing | consistency |

| Common Challenges in Automotive Hardness Testing | variability |

| Selecting Hardness Testers for Automotive Industry | buying guide |

| Role of Hardness Testing in Automotive R&D | innovation |

| Sustainability and Material Optimization | lightweight design |

| Brand Expertise and Automotive Solutions | Johoyd hardness testing |

| Future Trends in Automotive Hardness Testing | smart factories |

| Preguntas frecuentes | common questions |

| Conclusion | summary |

Introduction

Hardness testing for automotive industry plays a crucial role in ensuring vehicle safety, durability, and performance. Modern vehicles rely on a wide range of metallic components that must meet strict hardness requirements to withstand mechanical stress, wear, and environmental conditions.

From engine parts to structural components, hardness testing supports quality control, process optimization, and regulatory compliance across automotive manufacturing.

Hardness Testing for Automotive Industry

Hardness testing for automotive industry involves measuring a material’s resistance to indentation or deformation. These measurements help manufacturers verify material properties and confirm process consistency.

Reliable hardness data supports safe vehicle design.

Definition of Hardness Testing in Automotive

Hardness testing in automotive manufacturing refers to standardized testing methods used to assess the hardness of metals and alloys used in vehicle components.

It provides fast and reliable property evaluation.

Role of Hardness Testing in Automotive Manufacturing

Hardness testing ensures that components meet design specifications before assembly. It helps detect improper heat treatment, material defects, or processing errors.

Quality begins with verification.

Importance of Hardness Control in Vehicles

Incorrect hardness can lead to premature wear, fatigue failure, or catastrophic component failure. Proper hardness control improves durability and safety.

Hardness protects performance.

Evolution of Hardness Testing in Automotive Industry

Automotive hardness testing evolved from manual bench testers to digital, automated, and inline systems. Modern systems integrate data management and automation.

Technology improves consistency.

Common Materials Used in Automotive Industry

Automotive manufacturing uses steels, aluminum alloys, cast irons, and specialty alloys. Each material requires specific hardness testing methods.

Material choice defines testing needs.

Automotive Components Requiring Hardness Testing

Critical components include gears, crankshafts, camshafts, bearings, fasteners, suspension parts, and structural components.

Every component matters.

Hardness Testing Standards for Automotive

Automotive hardness testing follows international standards such as ASTM and ISO. These standards ensure consistency and global acceptance.

Standards support compliance.

Rockwell Hardness Testing in Automotive

Rockwell testing is widely used for production-line testing due to speed and simplicity. It is suitable for steels and heat-treated components.

Efficiency supports mass production.

Brinell Hardness Testing for Automotive Parts

Brinell testing is commonly applied to castings and large components. It provides average hardness values over a larger area.

Ideal for rough structures.

Vickers Hardness Testing for Automotive

Vickers testing offers high precision and is used for thin sections and small components.

Precision supports engineering decisions.

Microhardness Testing in Automotive

Microhardness testing evaluates surface-hardened layers, coatings, and heat-affected zones.

Surface integrity matters.

Portable Hardness Testing for Automotive

Portable hardness testers enable on-site inspection of large or assembled components. They reduce downtime and improve flexibility.

Mobility saves time.

Inline Hardness Testing in Automotive Production

Inline systems perform real-time hardness testing on production lines. They support immediate process control.

Real-time data prevents defects.

Non-Destructive Hardness Testing

Non-destructive methods preserve components while verifying hardness. They are essential for finished or in-service parts.

Preservation supports reliability.

Hardness Testing for Heat-Treated Automotive Parts

Heat treatment verification relies heavily on hardness testing. Incorrect hardness indicates improper processing.

Verification ensures consistency.

Hardness Testing for Welded Automotive Components

Weld hardness testing identifies potential brittleness or weakness in welded joints.

Weld quality ensures safety.

Hardness Testing for Engine Components

Engine parts experience extreme loads and temperatures. Hardness testing ensures wear resistance and fatigue strength.

Engines demand reliability.

Hardness Testing for Transmission Parts

Transmission components require precise hardness control to handle torque and friction.

Precision supports smooth operation.

Hardness Testing for Chassis and Suspension

Structural components must balance strength and flexibility. Hardness testing supports structural integrity.

Safety depends on structure.

Hardness Testing for Automotive Fasteners

Fasteners require consistent hardness to ensure proper clamping force.

Small parts have big impact.

Automation in Automotive Hardness Testing

Automated hardness testers improve throughput and reduce operator influence.

Automation increases efficiency.

Digital Hardness Testers in Automotive

Digital systems provide accurate measurement, data storage, and traceability.

Digital data supports audits.

Data Management and Traceability

Automotive manufacturers rely on traceable hardness data for quality records and compliance.

Traceability builds trust.

Calibration and Accuracy in Automotive Testing

Regular calibration ensures consistent results and compliance with standards.

Accuracy ensures confidence.

Common Challenges in Automotive Hardness Testing

Challenges include material variability, surface conditions, and high production speed.

Proper systems reduce challenges.

Selecting Hardness Testers for Automotive Industry

Selection depends on component size, material, testing volume, and automation requirements.

Correct choice maximizes value.

Role of Hardness Testing in Automotive R&D

R&D teams use hardness testing to develop lightweight materials and improve performance.

Innovation relies on data.

Sustainability and Material Optimization

Hardness testing supports optimized material usage, reducing waste and improving efficiency.

Sustainability matters.

Brand Expertise and Automotive Solutions

Reliable hardness testing for automotive industry requires robust equipment and application expertise. Johoyd, through https://hardnesstests.com, provides professional hardness testing machines and solutions designed for automotive manufacturing, quality control, and research, delivering precision, durability, and compliance with international standards.

Future Trends in Automotive Hardness Testing

Future trends include AI-driven analysis, fully automated inline systems, and smart factory integration.

The future is intelligent.

Frequently Asked Questions

Why is hardness testing important in automotive industry?

It ensures safety, durability, and consistent quality.

Which hardness test is most used in automotive?

Rockwell testing is widely used for production.

Is hardness testing non-destructive?

Many methods are minimally invasive or non-destructive.

Can hardness testing be automated?

Yes, automation is common in modern plants.

Which standards apply to automotive hardness testing?

ASTM and ISO standards are widely used.

Is portable hardness testing reliable?

Yes, when properly calibrated.

Conclusion

Hardness testing for automotive industry is essential for producing safe, durable, and high-performance vehicles. It supports quality assurance, process control, and innovation across automotive manufacturing.

With advanced hardness testing solutions from Johoyd available at hardnesstests.com, automotive manufacturers gain reliable tools that meet the demands of modern production environments. As vehicles evolve, hardness testing will continue to be a cornerstone of automotive quality and safety.

Suggested Internal Links

- Hardness Testing Machine

- Inline Hardness Testing

Suggested Outbound Links

- ASTM Automotive Material Standards

- ISO Automotive Testing Guidelines