Hardness Tester for Manufacturing Power Guide Essential Solutions for Reliable Production

Outline for the Article on Hardness Tester for Manufacturing

| Topic Area | Detailed Coverage with LSI Keywords |

|---|---|

| Introduction to Hardness Tester for Manufacturing | manufacturing hardness testing |

| What Is a Hardness Tester for Manufacturing | material verification |

| Importance of Hardness Testing in Manufacturing | consistency, reliability |

| Evolution of Hardness Testing in Manufacturing | industrial development |

| Basic Principles of Hardness Testing | indentation resistance |

| Common Hardness Testing Methods in Manufacturing | Rockwell, Brinell, Vickers |

| Rockwell Hardness Tester for Manufacturing | production-line testing |

| Brinell Hardness Tester for Manufacturing | cast and forged parts |

| Vickers Hardness Tester for Manufacturing | precision measurement |

| Microhardness Tester in Manufacturing | coatings and thin layers |

| Macro Hardness Tester in Manufacturing | bulk material testing |

| Portable Hardness Tester for Manufacturing | on-site inspection |

| Laboratory Hardness Tester for Manufacturing | controlled testing |

| Digital Hardness Tester for Manufacturing | data-driven inspection |

| Automatic Hardness Tester for Manufacturing | high-volume efficiency |

| Materials Tested in Manufacturing | metals and alloys |

| Hardness Testing for Steel Manufacturing | heat treatment control |

| Hardness Testing for Aluminum Manufacturing | lightweight components |

| Hardness Testing for Cast Iron Manufacturing | coarse structures |

| Hardness Testing for Non-Ferrous Metals | copper and brass |

| Hardness Testing in Incoming Inspection | supplier quality |

| Hardness Testing in In-Process Manufacturing | process control |

| Hardness Testing in Final Manufacturing Inspection | acceptance testing |

| Manufacturing Standards and Regulations | ASTM, ISO |

| Accuracy and Repeatability in Manufacturing | process reliability |

| Calibration and Traceability | quality assurance |

| Selecting the Right Hardness Tester for Manufacturing | application-based choice |

| Advantages of Hardness Testers in Manufacturing | defect reduction |

| Limitations of Hardness Testing in Manufacturing | interpretation |

| Safety Practices | operator safety |

| Maintenance of Manufacturing Hardness Testers | long-term accuracy |

| Interpreting Manufacturing Hardness Results | data analysis |

| Brand Expertise and Solutions | Johoyd manufacturing testers |

| Common Manufacturing Testing Errors | prevention |

| Future Trends in Manufacturing Hardness Testing | smart factories |

| Preguntas frecuentes | common questions |

| Conclusion | summary |

Introduction

Hardness Tester for Manufacturing processes plays a central role in ensuring product quality, consistency, and performance. Manufacturing environments rely on precise material properties to meet functional and safety requirements. Even minor variations in hardness can lead to defects, excessive wear, or premature failure.

Hardness testing provides manufacturers with a fast, reliable, and cost-effective way to verify material integrity throughout production. From raw materials to finished products, hardness testers support stable processes and high-quality output across diverse manufacturing industries.

Hardness Tester for Manufacturing

A Hardness Tester for Manufacturing is a testing instrument used to measure a material’s resistance to permanent deformation. This resistance reflects the material’s strength, wear resistance, and durability.

Because hardness correlates strongly with mechanical properties, hardness testing is widely used as a non-destructive quality control method in manufacturing environments.

Importance of Hardness Testing in Manufacturing

Hardness testing is critical because manufacturing processes such as forging, casting, machining, and heat treatment directly affect material properties. Incorrect hardness often indicates process deviations.

By integrating hardness testers into manufacturing workflows, companies detect issues early, reduce rework, and maintain consistent product quality.

Evolution of Hardness Testing in Manufacturing

Early manufacturing relied on manual inspection and basic mechanical tests. As production volumes increased, standardized hardness testing methods emerged.

Today, digital and automatic hardness testers support high-speed manufacturing and real-time quality monitoring.

Basic Principles of Hardness Testing

Hardness testing is based on resistance to indentation. A standardized indenter applies a controlled force to the material surface.

The size or depth of the indentation determines the hardness value. Different testing methods suit different materials and applications.

Common Hardness Testing Methods in Manufacturing

Manufacturing environments use several hardness testing methods. Each method offers unique advantages.

Rockwell, Brinell, and Vickers testing are the most commonly applied across manufacturing sectors.

Rockwell Hardness Tester for Manufacturing

Rockwell hardness testers measure indentation depth and provide rapid results.

They are ideal for high-throughput manufacturing lines, especially for steel components.

Brinell Hardness Tester for Manufacturing

Brinell testing uses a large ball indenter and heavy load.

It is suitable for cast iron, forgings, and materials with coarse grain structures.

Vickers Hardness Tester for Manufacturing

Vickers testing uses a diamond pyramid indenter.

It offers high accuracy across a wide hardness range and supports both macro and micro testing.

Microhardness Tester in Manufacturing

Microhardness testing evaluates thin coatings, surface treatments, and heat-affected zones.

It is essential for precision manufacturing and advanced materials.

Macro Hardness Tester in Manufacturing

Macro hardness testing evaluates bulk material properties.

This method ensures structural strength and durability of manufactured components.

Portable Hardness Tester for Manufacturing

Portable hardness testers allow on-site testing of large or installed parts.

They are useful for maintenance, audits, and large-scale manufacturing operations.

Laboratory Hardness Tester for Manufacturing

Laboratory testers provide controlled testing conditions and high precision.

They are used for certification, research, and reference measurements.

Digital Hardness Tester for Manufacturing

Digital testers reduce operator error and improve repeatability.

They offer data storage, reporting, and integration with manufacturing quality systems.

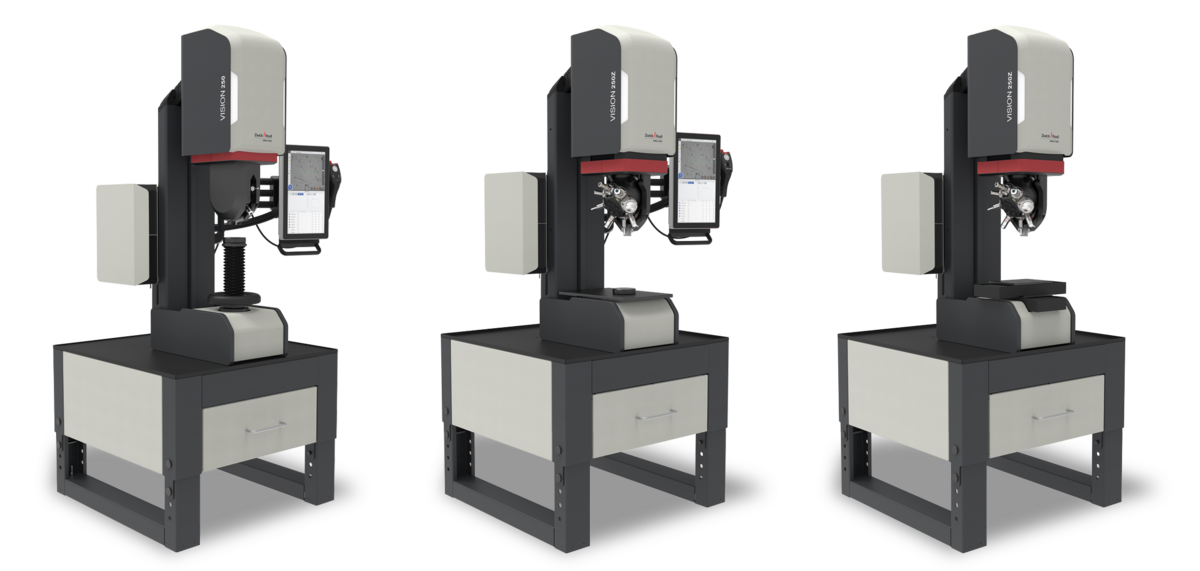

Automatic Hardness Tester for Manufacturing

Automatic hardness testers control loading, measurement, and result evaluation automatically.

They support high-volume manufacturing and consistent inspection.

Materials Tested in Manufacturing

Manufacturing hardness testing applies to metals and alloys.

Steel, aluminum, cast iron, and non-ferrous metals are commonly tested.

Hardness Testing for Steel Manufacturing

Steel manufacturing relies heavily on hardness testing to verify heat treatment.

Correct hardness ensures strength, wear resistance, and safety.

Hardness Testing for Aluminum Manufacturing

Aluminum components require careful testing due to lower hardness.

Vickers or Brinell testing ensures accurate results.

Hardness Testing for Cast Iron Manufacturing

Cast iron has a heterogeneous structure.

Brinell testing provides reliable average hardness values.

Hardness Testing for Non-Ferrous Metals

Copper, brass, and similar materials require precise load control.

Vickers testing offers flexibility and accuracy.

Hardness Testing in Incoming Inspection

Incoming inspection verifies supplier materials before production.

Hardness testing prevents defective materials from entering manufacturing processes.

Hardness Testing in In-Process Manufacturing

In-process hardness testing monitors production consistency.

It allows immediate adjustments to maintain quality.

Hardness Testing in Final Manufacturing Inspection

Final inspection confirms that finished products meet specifications.

Hardness testing supports acceptance decisions.

Manufacturing Standards and Regulations

Hardness testing in manufacturing follows ASTM and ISO standards.

Compliance ensures consistency and traceability.

Accuracy and Repeatability in Manufacturing

Accuracy depends on calibration, surface preparation, and test method selection.

Repeatability ensures reliable production decisions.

Calibration and Traceability

Regular calibration maintains accuracy.

Traceable results support audits and quality certification.

Selecting the Right Hardness Tester for Manufacturing

Selection depends on material type, production volume, and testing environment.

Expert guidance ensures optimal equipment choice.

Advantages of Hardness Testers in Manufacturing

Key advantages include:

- Fast inspection

- Early defect detection

- Minimal material damage

- Strong correlation with performance

These benefits improve manufacturing efficiency.

Limitations of Hardness Testing in Manufacturing

Hardness testing does not measure all mechanical properties.

Results require proper interpretation.

Safety Practices

Operators should follow safety guidelines during testing.

Training reduces risk and improves accuracy.

Maintenance of Manufacturing Hardness Testers

Routine cleaning, inspection, and calibration maintain accuracy.

Proper maintenance extends equipment lifespan.

Interpreting Manufacturing Hardness Results

Results should be evaluated based on material grade and process history.

Expert analysis ensures valid conclusions.

Brand Expertise and Solutions

Reliable manufacturing inspection requires dependable equipment. Brands like Johoyd, through https://hardnesstests.com, provide professional Hardness Tester for Manufacturing solutions designed for production floors, laboratories, and field inspection.

Their expertise ensures accuracy, durability, and confidence in manufacturing quality.

Common Manufacturing Testing Errors

Common errors include poor surface preparation and incorrect test selection.

Standardized procedures reduce mistakes.

Future Trends in Manufacturing Hardness Testing

Future trends include smart testers, automation, and integration with digital manufacturing systems.

These innovations support Industry automation and smart factories.

Frequently Asked Questions

What is a hardness tester for manufacturing used for?

It verifies material strength and consistency.

Which hardness test is common in manufacturing?

Rockwell testing is widely used.

Can hardness testing be automated?

Yes, automatic systems support high-volume production.

Is hardness testing destructive?

It is minimally destructive.

Can portable testers be used in manufacturing?

Yes, for large or installed components.

How often should hardness testers be calibrated?

According to standards or usage frequency.

Conclusion

Hardness Tester for Manufacturing applications are essential for maintaining product quality, process stability, and operational efficiency. By providing fast and reliable material verification, hardness testing supports every stage of manufacturing.

With trusted manufacturers like Johoyd delivering advanced solutions through hardnesstests.com, manufacturers gain confidence in their quality systems. As production technology advances, hardness testers will remain a cornerstone of modern manufacturing.

Suggested Internal Links

- Industrial Hardness Testing Equipment

- Manufacturing Quality Control Tools

Suggested Outbound Links

- ASTM Manufacturing Hardness Testing Standards

- ISO Industrial Measurement Guidelines