Sample Grinding and Polishing: A Comprehensive Guide

In materials science and metallography, the preparation of samples is a crucial step for accurate microstructural analysis. Among the most critical processes in sample preparation are grinding and polishing, which produce a smooth, defect-free surface suitable for microscopic examination. Proper grinding and polishing allow scientists and engineers to observe the true microstructure of metals, ceramics, composites, and other materials.

1. Introduction

Before examining a material under a microscope, its surface must be free of scratches, deformation, and oxidation. Sample grinding and polishing achieve this by progressively removing surface layers through mechanical abrasion.

These processes are essential in:

- Metallographic analysis

- Failure investigation of components

- Material quality control

- Research and development of new alloys or composites

Without proper grinding and polishing, microstructural features such as grains, inclusions, and phases may be obscured or misinterpreted.

2. Objectives of Grinding and Polishing

The main goals of grinding and polishing are:

- Flattening the sample: Removing irregularities from sectioning and mounting.

- Removing surface damage: Eliminating scratches, deformation, or strains introduced during cutting or handling.

- Preparing for etching: Providing a mirror-like surface for chemical etching to reveal microstructures.

- Ensuring reproducibility: Allowing consistent results across different samples and analyses.

3. Sample Preparation Overview

Before grinding and polishing, samples often undergo the following preparatory steps:

- Sectioning: Cutting the material into a manageable size using a diamond or abrasive saw.

- Mounting: Embedding the sample in resin or epoxy for easier handling. Mounting can be cold mounting (room temperature) or hot mounting (using heat and pressure).

Once mounted, the sample is ready for grinding and polishing.

4. Grinding Process

a) Purpose of Grinding

Grinding removes saw marks and surface irregularities from sectioned samples. It also ensures a flat and uniform surface before polishing.

b) Equipment Used

- Grinding machines: Equipped with rotating abrasive discs or belts.

- Abrasives: Silicon carbide (SiC) papers with varying grit sizes, typically ranging from 120 to 1200 grit or higher.

c) Grinding Steps

- Start with coarse grit (e.g., 120–240) to remove large surface defects.

- Progressively move to finer grits (e.g., 400, 600, 800, 1200) to smooth the surface.

- Maintain consistent pressure and movement to avoid uneven wear or deformation.

- Rinse the sample between grit changes to remove abrasive particles and prevent contamination.

Tips:

- Use a water or oil lubricant to reduce heat and prevent surface damage.

- Grind in one direction per grit size, then rotate 90° for the next grit for uniformity.

5. Polishing Process

a) Purpose of Polishing

Polishing removes fine scratches left by grinding and produces a mirror-like finish, necessary for clear microstructural observation.

b) Equipment and Materials

- Polishing cloths: Made of soft fabric, often with woven or velvet surfaces.

- Abrasives: Diamond suspensions (0.25–6 μm), alumina, or colloidal silica for final polishing.

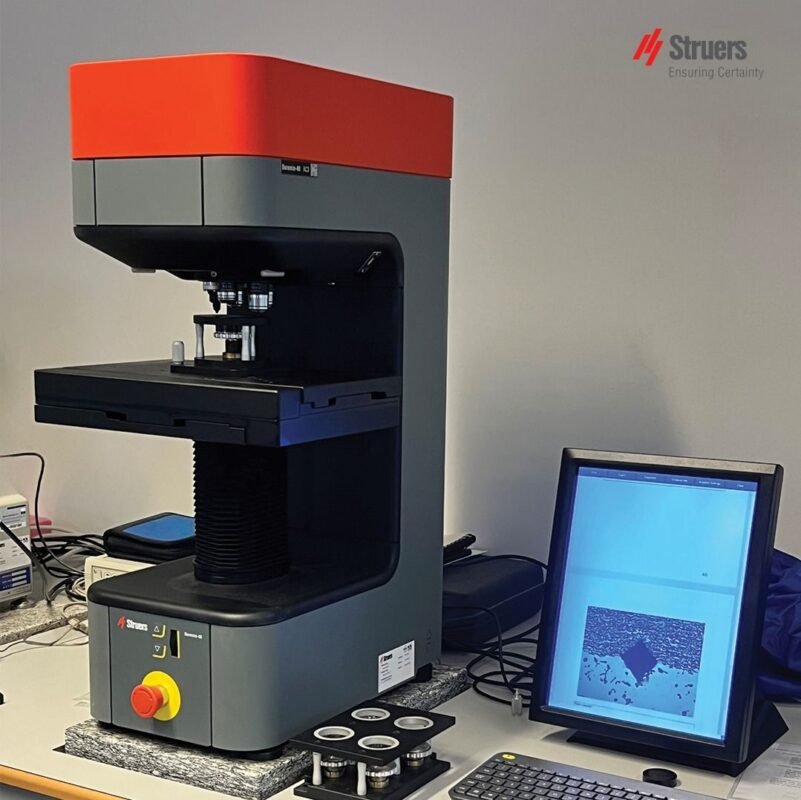

- Polishing machines: Motorized plates with controlled rotation speed and pressure.

c) Polishing Steps

- Rough Polishing: Use 6–3 μm diamond suspension to remove coarse scratches.

- Fine Polishing: Use 1–0.25 μm diamond or alumina suspension to achieve a near-mirror finish.

- Final Polishing: Often uses colloidal silica (0.05 μm) to remove deformation and achieve the best surface quality.

Tips:

- Keep the surface and cloth wet to avoid heat buildup.

- Change polishing cloths regularly to prevent contamination.

- Inspect the surface under a low-power microscope to check for scratches or damage.

6. Common Problems and Solutions

| Problem | Cause | Solution |

|---|---|---|

| Scratches after polishing | Dirty cloth, abrasive contamination | Replace cloth, clean sample, use fresh abrasive |

| Uneven surface | Uneven pressure, worn abrasive | Apply uniform pressure, replace abrasive |

| Smearing on soft metals | Excessive heat or pressure | Reduce pressure, use appropriate lubricant |

| Sample edge rounding | Aggressive grinding | Use finer grit earlier, reduce pressure |

7. Applications of Grinding and Polishing

Properly prepared samples are critical for:

- Metallographic analysis: Revealing grain boundaries, phases, and inclusions.

- Failure analysis: Identifying cracks, corrosion, and fatigue features.

- Material research: Studying deformation, phase transformations, and coatings.

- Quality control: Ensuring consistency and compliance with material standards.

8. Conclusion

Sample grinding and polishing are fundamental steps in metallography and materials science. By producing a smooth, defect-free surface, these processes allow accurate observation and analysis of microstructures. Careful selection of abrasives, consistent technique, and attention to detail are key to achieving high-quality results. Properly prepared samples lead to reliable data, supporting research, manufacturing, and quality assurance efforts.