Malzeme Sertlik Analizi Kanıtlanmış Kılavuz Doğru Özellik Değerlendirmesi için Akıllı Yöntemler

Outline for the Article on Material Hardness Analysis

| Konu Alanı | LSI Anahtar Kelimeleriyle Detaylı Kapsam |

|---|---|

| Introduction to Material Hardness Analysis | hardness analysis methods |

| Definition of Material Hardness Analysis | material property evaluation |

| Importance of Hardness Analysis | performance and durability |

| Role of Hardness Analysis in Material Science | structure–property relationship |

| Evolution of Material Hardness Analysis | test teknolojisi geliştirme |

| Fundamental Principles of Hardness | deformasyona karşı direnç |

| Relationship Between Hardness and Strength | mechanical properties |

| Core Elements of Material Hardness Analysis | load, indenter, measurement |

| Types of Hardness Analysis Methods | Rockwell, Brinell, Vickers |

| Rockwell Hardness Analysis | depth-based analysis |

| Brinell Hardness Analysis | indentation diameter evaluation |

| Vickers Hardness Analysis | optical precision analysis |

| Knoop Hardness Analysis | mi̇krosertli̇k değerlendi̇rmesi̇ |

| Microhardness Analysis | kaplamalar ve ince tabakalar |

| Macro Hardness Analysis | bulk material behavior |

| Digital Hardness Analysis | elektroni̇k ölçüm |

| Automatic Hardness Analysis Systems | automated evaluation |

| Portable Hardness Analysis | saha deneti̇mi̇ |

| Laboratory Hardness Analysis | kontrollü test |

| Materials Used in Hardness Analysis | metaller ve alaşimlar |

| Hardness Analysis of Steel | heat treatment assessment |

| Hardness Analysis of Aluminum | alloy consistency |

| Hardness Analysis of Cast Iron | yapisal malzemeler |

| Hardness Analysis of Non-Ferrous Metals | bakır ve alaşımları |

| Sample Preparation for Hardness Analysis | yüzey durumu |

| Üretim Alanındaki Uygulamalar | süreç optimizasyonu |

| Kalite Kontrol Uygulamaları | acceptance criteria |

| Ar-Ge Laboratuvarlarındaki Uygulamalar | malzeme geliştirme |

| Applications in Failure Analysis | root cause study |

| Hardness Analysis in Automotive Industry | güvenlik açısından kritik parçalar |

| Hardness Analysis in Aerospace Industry | compliance testing |

| Standards for Material Hardness Analysis | ASTM, ISO |

| Doğruluk ve Tekrarlanabilirlik | data reliability |

| Kalibrasyon ve İzlenebilirlik | ölçüm güveni̇ |

| Data Interpretation and Reporting | engineering decisions |

| Selecting Equipment for Hardness Analysis | seçi̇m kilavuzu |

| Common Errors in Hardness Analysis | prevention methods |

| Advantages of Material Hardness Analysis | efficiency and insight |

| Limitations of Hardness Analysis | interpretation boundaries |

| Maintenance of Hardness Analysis Equipment | long-term accuracy |

| Integration with Digital Systems | smart manufacturing |

| Marka Uzmanlığı ve Çözümleri | Johoyd hardness analysis |

| Future Trends in Hardness Analysis | AI and automation |

| SSS | ortak sorular |

| Sonuç | özet |

Giriş

Material Hardness Analysis is a fundamental approach used to evaluate the mechanical behavior of materials by measuring their resistance to deformation. Across manufacturing, research, and quality assurance, hardness analysis provides a fast and reliable indication of material strength, wear resistance, and structural integrity.

Because hardness is closely related to other mechanical properties, material hardness analysis plays a critical role in material selection, process control, and failure prevention. From laboratories to production floors, it remains one of the most widely applied material evaluation techniques.

Material Hardness Analysis

Material Hardness Analysis refers to the systematic measurement and interpretation of a material’s hardness to understand its mechanical performance. It involves applying a controlled force to a material surface and analyzing the resulting deformation.

The results support engineering decisions throughout the product lifecycle.

Definition of Material Hardness Analysis

Material hardness analysis is the process of determining a material’s resistance to localized plastic deformation using standardized testing methods. The analysis includes both the measurement itself and the interpretation of results in relation to material behavior.

This process provides quantitative data that can be compared against specifications and standards.

Importance of Hardness Analysis

Hardness analysis is important because it offers a quick and cost-effective way to evaluate material quality. Variations in hardness often indicate changes in composition, heat treatment, or processing conditions.

By identifying these variations, material hardness analysis helps prevent performance issues and failures.

Role of Hardness Analysis in Material Science

In material science, hardness analysis helps link microstructure to mechanical properties. Changes in grain size, phase distribution, or treatment history often reflect directly in hardness values.

This makes hardness analysis a powerful research and diagnostic tool.

Evolution of Material Hardness Analysis

Early hardness analysis relied on simple scratch tests and manual indentation methods. These techniques provided basic comparisons but lacked precision.

Modern material hardness analysis uses standardized methods, digital measurement, and automated systems to deliver accurate and repeatable results.

Fundamental Principles of Hardness

Hardness is defined as resistance to permanent deformation. In material hardness analysis, this resistance is measured by applying a load through a specific indenter shape.

The size or depth of the indentation reflects the material’s hardness.

Relationship Between Hardness and Strength

Hardness often correlates with tensile strength and wear resistance. While it does not replace full mechanical testing, hardness analysis provides valuable insight into material performance.

This correlation makes hardness testing widely used in engineering practice.

Core Elements of Material Hardness Analysis

Effective material hardness analysis requires controlled loading, standardized indenters, accurate measurement, and proper interpretation.

Each element contributes to reliable and comparable results.

Types of Hardness Analysis Methods

Several standardized hardness analysis methods are used depending on material type and application.

The most common include Rockwell, Brinell, Vickers, and Knoop methods.

Rockwell Hardness Analysis

Rockwell hardness analysis measures indentation depth under load. It provides fast results and is ideal for production and quality control.

Minimal sample preparation is required.

Brinell Hardness Analysis

Brinell hardness analysis evaluates indentation diameter from a large ball indenter. It is suitable for coarse-grained and bulk materials.

This method averages material heterogeneity.

Vickers Hardness Analysis

Vickers hardness analysis uses a diamond pyramid indenter and optical measurement. It offers high precision across a wide hardness range.

It is widely used in laboratories.

Knoop Hardness Analysis

Knoop hardness analysis is a microhardness method for thin layers and brittle materials. It produces elongated indentations that reduce cracking risk.

It is useful for coatings and microstructures.

Microhardness Analysis

Microhardness analysis uses low loads to evaluate small features. It is essential for thin coatings, surface treatments, and fine structures.

Precision is a key advantage.

Macro Hardness Analysis

Macro hardness analysis applies higher loads to assess bulk material behavior. It is commonly used for structural components.

It reflects overall material strength.

Digital Hardness Analysis

Digital hardness analysis uses electronic sensors and software. It reduces operator influence and improves repeatability.

Digital data supports traceability.

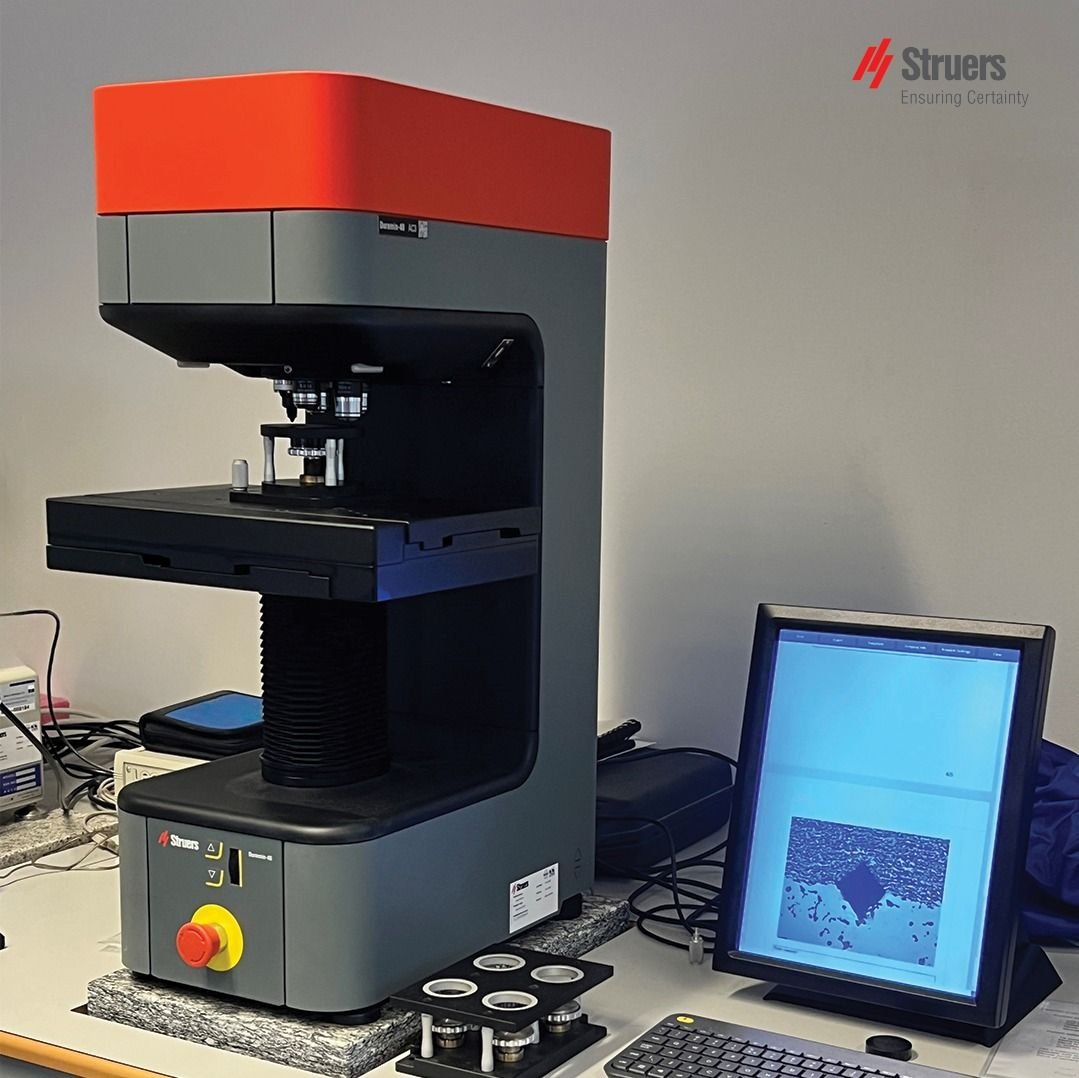

Automatic Hardness Analysis Systems

Automatic systems control the entire testing process. They are ideal for high-volume and standardized analysis.

Automation improves efficiency and consistency.

Portable Hardness Analysis

Portable hardness analysis enables on-site testing of large or installed components. It supports maintenance and inspection tasks.

Results are obtained without sample removal.

Laboratory Hardness Analysis

Laboratory hardness analysis provides reference-level accuracy. Controlled conditions ensure reliable comparison and validation.

It is widely used in research and certification.

Materials Used in Hardness Analysis

Material hardness analysis is most commonly applied to metals and alloys. Steel, aluminum, cast iron, and non-ferrous metals are frequently tested.

Each material requires appropriate method selection.

Hardness Analysis of Steel

Steel hardness analysis verifies heat treatment and strength. It is critical for structural and safety-related components.

Rockwell and Vickers methods are commonly used.

Hardness Analysis of Aluminum

Aluminum alloys require careful hardness analysis due to lower strength. Vickers testing is often preferred for precision.

Analysis ensures alloy consistency.

Hardness Analysis of Cast Iron

Cast iron hardness analysis supports quality control of industrial components. Brinell testing is commonly applied.

It accounts for material heterogeneity.

Hardness Analysis of Non-Ferrous Metals

Non-ferrous metals require precise analysis. Microhardness methods are often used for thin or soft materials.

Hardness analysis supports electrical and thermal applications.

Sample Preparation for Hardness Analysis

Proper surface preparation ensures accurate results. Flat, smooth surfaces reduce measurement error.

Poor preparation can distort analysis.

Üretim Alanındaki Uygulamalar

Manufacturers use material hardness analysis for process control. It verifies consistency during production.

Quick feedback supports corrective action.

Kalite Kontrol Uygulamaları

Quality control hardness analysis ensures materials meet specifications. It supports acceptance and rejection decisions.

Consistency is critical.

Ar-Ge Laboratuvarlarındaki Uygulamalar

R&D laboratories use hardness analysis to study material behavior. It supports development and optimization.

Hardness trends guide innovation.

Applications in Failure Analysis

Failure analysis uses hardness data to identify processing or service issues. Variations often reveal root causes.

Hardness analysis complements metallography.

Hardness Analysis in Automotive Industry

Automotive components rely on hardness analysis for safety. It ensures durability and performance.

Quality standards are strict.

Hardness Analysis in Aerospace Industry

Aerospace applications demand precise hardness analysis. Traceability and compliance are essential.

Safety-critical components depend on accurate data.

Standards for Material Hardness Analysis

Material hardness analysis follows ASTM and ISO standards. Standardization ensures global comparability.

Compliance builds confidence.

Doğruluk ve Tekrarlanabilirlik

Accuracy ensures correct hardness values. Repeatability ensures consistent interpretation.

Both are essential for reliable analysis.

Kalibrasyon ve İzlenebilirlik

Regular calibration maintains confidence in hardness analysis. Traceability supports audits and certifications.

It is a core quality requirement.

Data Interpretation and Reporting

Hardness data must be interpreted correctly. Proper reporting supports engineering decisions.

Digital systems simplify documentation.

Selecting Equipment for Hardness Analysis

Selection depends on material, hardness range, and application. Expert guidance ensures optimal analysis.

The right equipment improves results.

Common Errors in Hardness Analysis

Errors include poor preparation, incorrect loads, and improper calibration. Standard procedures reduce risk.

Training is essential.

Advantages of Material Hardness Analysis

Temel avantajlar şunlardır:

- Fast evaluation

- Cost-effective testing

- Strong property correlation

- Wide applicability

These benefits make hardness analysis indispensable.

Limitations of Hardness Analysis

Hardness analysis does not measure all properties. Results must be interpreted in context.

It complements, not replaces, other tests.

Maintenance of Hardness Analysis Equipment

Routine maintenance preserves accuracy. Proper care extends equipment lifespan.

Consistent performance supports reliable analysis.

Integration with Digital Systems

Modern hardness analysis integrates with digital manufacturing systems. Data supports smart quality control.

Connectivity enhances efficiency.

Marka Uzmanlığı ve Çözümleri

Reliable Material Hardness Analysis requires precision equipment and expert support. Johoyd, aracılığıyla https://hardnesstests.com, provides advanced hardness analysis solutions designed for laboratories, manufacturing, and quality control, supporting accuracy, consistency, and compliance.

Future Trends in Hardness Analysis

Future trends include AI-assisted interpretation, automation, and deeper integration with smart factories. These innovations will enhance insight and efficiency.

Sıkça Sorulan Sorular

What is material hardness analysis used for?

It evaluates material resistance to deformation.

Is hardness analysis destructive?

Minimum düzeyde yıkıcıdır.

Does hardness correlate with strength?

Yes, it often correlates with tensile strength.

Are standards required for hardness analysis?

Evet, ASTM ve ISO standartları geçerlidir.

Can hardness analysis be automated?

Yes, many systems support automation.

Is sample preparation important?

Yes, it directly affects accuracy.

Sonuç

Material Hardness Analysis is a cornerstone of material evaluation, supporting manufacturing, research, and quality assurance. By providing fast, reliable insight into material behavior, it helps ensure safety, performance, and consistency.

Gibi güvenilir sağlayıcılarla Johoyd offering professional solutions through hardnesstests.com, organizations can rely on accurate and repeatable hardness analysis. As technology advances, material hardness analysis will continue to play a vital role in modern engineering.

Önerilen Dahili Bağlantılar

- Quality Control Hardness Testing

- Laboratory Hardness Testers

Önerilen Giden Bağlantılar

- ASTM Sertlik Test Standartları

- ISO Hardness Measurement Guidelines