- Appareil d'essai de dureté Micro Vickers

- Appareil d'essai de dureté Vickers

- Capteur de dureté Vickers

- Appareil d'essai de dureté Rockwell

- Appareil d'essai de dureté Brinell

- Appareil de dureté Leeb

- Appareil de mesure de la dureté Shore

- Testeur de dureté Webster

- Appareil de mesure de la dureté Barcol

- Barre d'essai de dureté

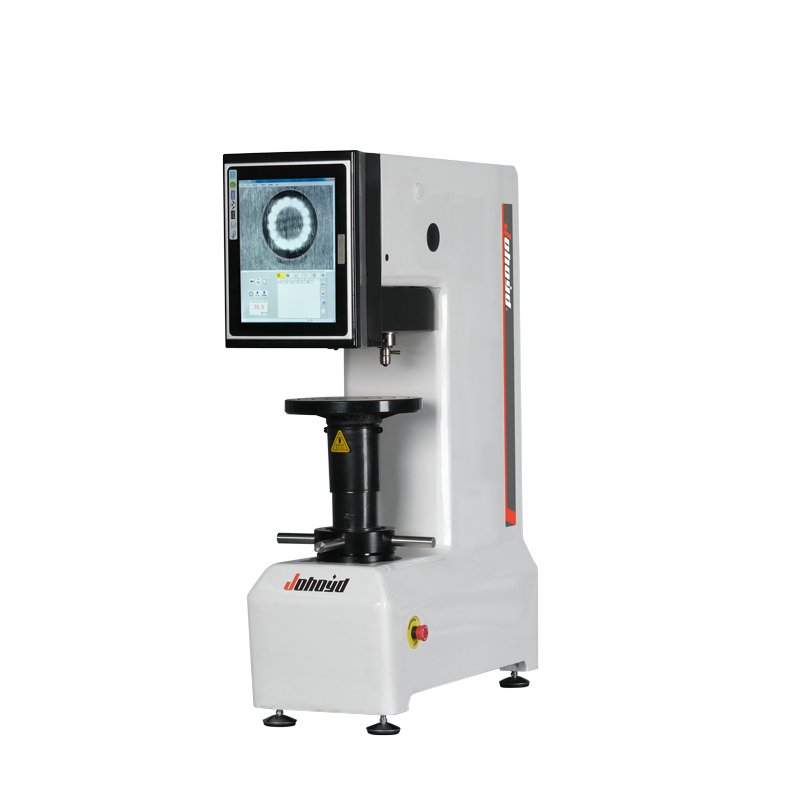

HVS-1000Z Digital Display Automatic Turret Microhardness Tester (Large Screen, Side-Shaking Lifting System)

This digital automatic turret microhardness tester can meet the basic Vickers hardness test requirements. The upgraded digital micrometer eyepiece can directly read the measured length, so as to obtain the measured value more quickly and accurately. The upgraded turret can automatically switch the eyepiece and the indenter to avoid damage to the instrument caused by human error, and also greatly improve efficiency. The large LCD screen is convenient for observation, and the test conditions and test process are intuitive.

Main functions and features:

- The optical system designed by senior optical engineers not only has clear images, but can also be used as a simple microscope. The brightness is adjustable, the vision is comfortable, and long-term operation is not easy to fatigue;

- The large LCD screen of the industrial display can display the test method, test force, measured indentation length, hardness value, converted hardness, test force holding time, number of measurements, and can enter the year, month, date, test results and data processing, etc.;

- The cast aluminum shell is formed in one step, the structure is stable and does not deform, the pure white car paint is high-grade, and the scratch resistance is strong. It is still bright as new after years of use;

- Our company has the ability to independently develop, design, produce and process, and the machine provides lifetime parts replacement and maintenance upgrade services;

- The HVS-1000Z model can realize: measuring the length directly to confirm the hardness value.

- The HVS-1000Z model can realize: the position switching of observation-testing-measurement is completed by the automatic turret.

- Our company has the ability to independently develop, design, produce and process, and our machine provides lifetime parts replacement and maintenance upgrade services;

Main uses and scope of application:

- Steel, non-ferrous metals, metal foils, hard alloys, metal sheets, microstructures

- Carburizing, nitriding and decarburizing layers, surface hardening layers, electroplating layers, coatings

- Glass, wafers

Technical Parameters:

| Parameter name | Parameter data |

| Microhardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 |

| Display | LCD display |

| Test force (gf) | 10, 25, 50, 100, 200, 300, 500, 1000 |

| Loading control | Automatic (load/hold/unload) |

| Test force holding time (s) | 5~60 |

| Test force selection | External force selection knob, test force is automatically displayed on the display |

| Objective magnification | 10×, 40× |

| Optical channel | Dual light channel (eyepiece and CCD camera channel) |

| Optical system (dual optical channels, no switching required) | 1. Automatic digital encoder; 2. Total magnification (μm): 100× (observation), 400× (measurement); |

| Hardness measurement range | Optional 15X eyepiece, total magnification: 150X (observation), 600X (measurement) |

| XY test table | 3. Measuring range (μm): 200; 4. Resolution (μm): 0.01 |

| Data output (optional) | (5-3000)HV |

| Maximum specimen height (mm) | Dimensions (mm): 100×100 Travel range (mm): 25×25 Minimum reading (mm): 0.01 |

| Maximum specimen width (mm) | Built-in printer, |

| Power supply voltage | 110 |

| Weight (kg) | 85 (distance from the center line of the pressure head to the machine wall) |

| Dimensions | AC220V/50HZ |

Standard Configuration

| 1. Main unit (one micro-Vickers indenter, one 10X and one 40X objective lens); | 2. Test bench, weights, microscope accessory box; |

| 3. Weights 6 pcs | 4. Weight rod 1 piece |

| 5. Cross workbench 1 pc | 6. Thin sheet clamping table 1 piece |

| 7. Flat clamping table 1 pc | 8. Wire clamping table 1 piece |

| 9. Level 1 pc | 10. Screwdriver 2 pieces |

| 11. Level adjustment screws 4 pcs | 12. External power cord 1 piece |

| 13. 10× micrometer eyepiece 1 pc | 14. Micro Vickers hardness block 2 pieces (one each for HV1 and HV0.2) |

| 15. Fuse (1 A) 2 pcs | 16. Product certificate 1 piece |

| 17. Product instruction manual 1 copy | 18. Dust cover 1 piece |

Soyez le premier à laisser votre avis sur “HVS-1000Z Digital Display Automatic Turret Microhardness Tester (Large Screen, Side-Shaking Lifting System)” Annuler la réponse

MAECENAS IACULIS

Vestibulum curae torquent diam diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

.jpg)

-400x400.jpg)

Avis

Il n’y a pas encore d’avis.