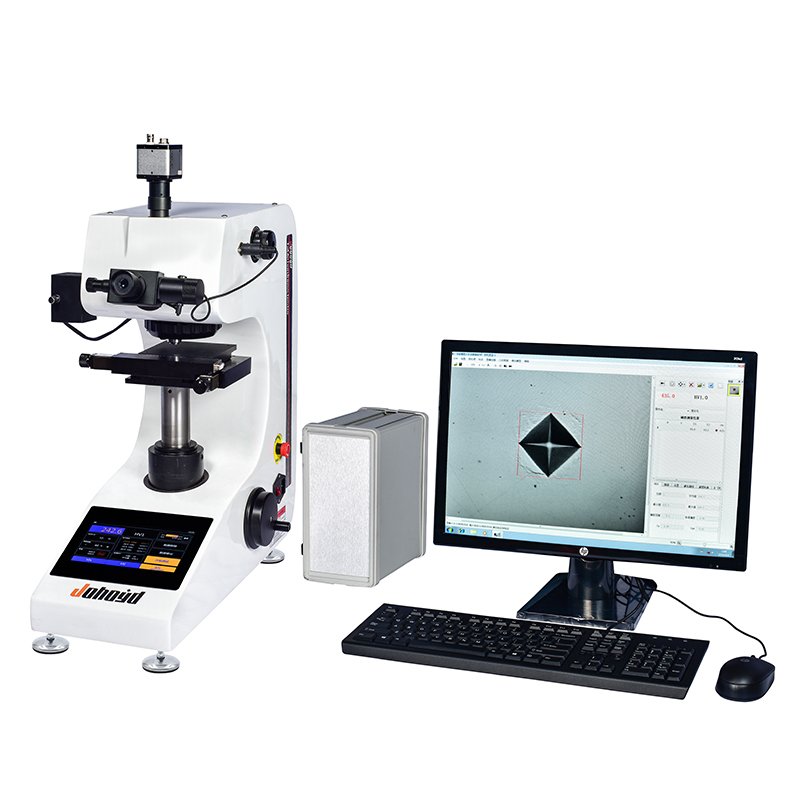

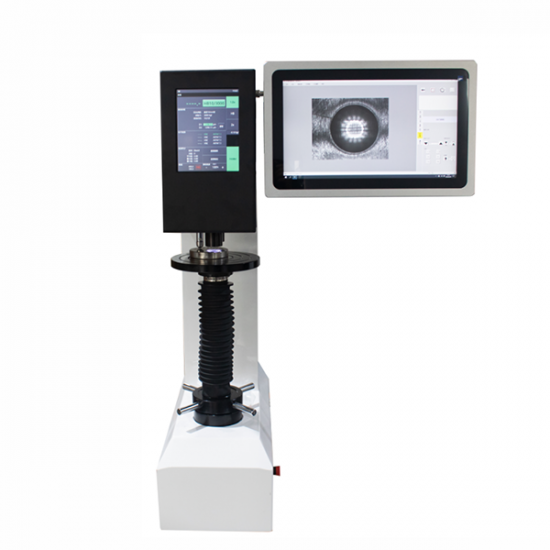

PCAHVST-1000ZXY Fully automatic micro Vickers hardness tester

The fully automatic microhardness tester is mainly used to measure tiny, thin specimens and brittle hardware. By selecting various accessories or upgrading various structures, it can be widely used for various metals (ferrous metals, non-ferrous metals, castings, alloy materials, etc.), metal structures, metal surface processing layers, electroplating layers, hardening layers (oxidation, various penetration layers, coating layers), heat-treated specimens, carburized specimens, quenched specimens, tiny parts of phase inclusions, glass, agate, artificial gems, ceramics and other brittle and hard non-metallic materials. It is especially suitable for mass measurement of hardness gradient distribution curves of workpieces and hardness testing of designated parts. It is controlled by the automatic translation stage controlled by a stepper motor and mouse clicks. It has a variety of control modes, high positioning accuracy, good repeatability, fast moving speed and high work efficiency.

Hardness tester technical parameters:

| Nombre del parámetro | Datos de los parámetros |

| Microhardness scale | HV0.01, HV0.025, HV0.05, HV0.1, HV0.2, HV0.3, HV0.5, HV1 |

| Mostrar | 10-inch touch screen |

| Fuerza de ensayo (gf) | 10, 25, 50, 100, 200, 300, 500, 1000 |

| Load control | Automatic (load/hold/unload) |

| Test force holding time (s) | 5~60 |

| Selección de la fuerza de ensayo | External force selection knob, test force is automatically displayed on the touch screen |

| Aumento objetivo | 10×,40× |

| Canal óptico | Dual light channel (eyepiece and CCD camera channel) |

| Rango de medición de la dureza | (5-3000)HV |

| Altura máxima de la probeta (mm) | 150 |

| Maximum specimen width (mm) | 120 (distance from the center line of the pressure head to the machine wall) |

| Power supply voltage | AC220V/50HZ |

| Peso (kg) | 50 |

Software parameters:

The fully automatic micro-Vickers hardness tester integrates the latest professional technologies such as optical imaging, mechanical displacement, electronic control, digital imaging, image analysis, and computer processing. It controls the Vickers hardness tester and the automatic stage through the computer host, and digitally images the hardness indentation on the computer screen. Then, it accurately measures the microhardness, hardened layer depth, film thickness, and two-point distance of metals and some non-metallic materials and various film layers and coatings through automatic reading and manual reading. It can perform successive experiments of adding loads and reading indentations each time. It uses a convenient CCD camera, which can directly observe the measured indentation on the display, with high measurement accuracy to avoid manual measurement errors. Setting test conditions and displaying results can be operated and displayed clearly and quickly. Through the measurement control software, it is easy to operate on the built-in computer, and single-point measurement can be achieved. It can randomly measure multiple points and statistically measure data. The distance between two or more measurement points can be arbitrarily set to measure the depth of the penetration layer. It can measure and statistically measure data in the X or Y direction, and automatically calculate the depth of the hardened layer according to the judgment value entered by the user. Statistical calculation, conversion, display curve to judge whether it is qualified, etc. It can measure the length of parts, save and print graphics, etc. It can also take pictures of the metal surface morphology and print it at a fixed rate. This system breaks through the traditional hardness test method and realizes fully automatic, high-precision, and high-repeatability hardness testing. It is an important equipment for material analysis.

MAECENAS IACULIS

Vestibulum curae torquent diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Valoraciones

No hay valoraciones aún.