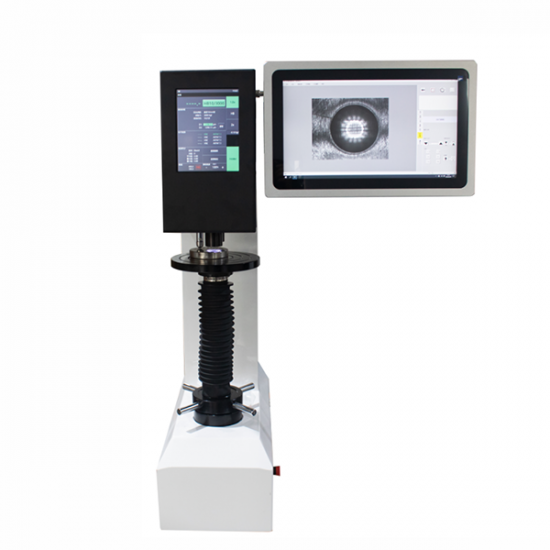

(HRTS-45) Durómetro Rockwell de superficie con pantalla digital táctil

HRTS-45 color touch screen digital display surface Rockwell hardness tester is our new generation of high-tech products with multi-function, high precision and stable performance. Its appearance is novel, the shell adopts one-piece casting, the stability is high, and its touch screen interface is menu-oriented , The operation is simple, intuitive and convenient. The measuring device adopts grating sensor and computer control. The hardness value is directly displayed on the LCD screen. It is a mechatronics hardness tester. Various hardness parameters can be automatically converted to each other, and the minimum thickness of the test piece can be identified. When testing the cylinder, the correction amount can be automatically added. Built-in printer to read relevant test results. Automatic operation is realized, and human operation and reading errors are eliminated! At the same time, the machine is also equipped with an emergency stop device, which is safer to use.

Principales funciones y características del instrumento

- The 7-inch LCD touch screen can directly display the hardness value, convert the hardness, test method, test force, brightness, initial test force retention time, total test force retention time, elastic recovery time, measurement times, statistical data, test time Wait for the test process to be intuitive and clear;

- The system comes with a calibration function, which can automatically adjust the error range of 80-120%, or calibrate the instrument separately for low and high values

- Al comprobar la superficie curva, se corrige automáticamente según el radio de superficie curva estándar;

- 100 sets of test data can be stored, and the test data can be viewed at any time, and the current data can also be deleted or all the test data can be cleared;

- The test force units can be converted mutually, the conversion unit is: (Kgf, N)

- Simultaneous display: maximum value, minimum value, average value, test times, product name;

- The main interface can display 4 conversion scales at the same time, and can switch: National Standard (GB), American Standard (ASTM) and International (ISO) Standards. A total of 20 measuring scales can be converted: HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HK, HBW, HS, HBS, HV, Rm (tensile strength),

- The screen sleep time can be set, and it will automatically enter the sleep state if it is not operated for a long time, saving environmental protection;

- The upper and lower limit measurement range can be set, displayed on the main measurement interface, and the unqualified value will automatically prompt an alarm;

- There are 14 languages in the operating system, which can be switched at will: Chinese, Traditional Chinese, English, Russian, German, French, Spanish, Portuguese, Turkish, Czech, Japanese, Korean, Thai, Vietnamese;

- Equipped with a built-in printer, test data can also be output to U disk via USB for storage and analysis;

- The casting shell has a stable and non-deformed structure once formed, the pure white car paint has a high grade, strong scratch resistance, and it is still bright as new after many years of use;

- Our company has the ability to develop, design and produce on its own. Our machines provide parts replacement and maintenance upgrade services for life;

The main purpose and scope of use of the instrument:

Surface hardened steel, copper, aluminum alloy sheet, strip steel, hard alloy steel

Various metal materials such as zinc plating, chrome plating, tin plating, material surface heat treatment and chemical surface treatment

Casting and forging parts ·Sample test and acceptance inspection

Flat and cylindrical workpieces · Steel, non-ferrous metals

Automobile and aviation industry · Cemented carbide, ceramics, stainless steel

Laboratory and workshop

Detailed instrument parameters:

| parameter name | Datos de los parámetros |

| Initial test force (N) | 3kgf(29.42N) Allowable error±2.0% |

| Total test force (N) | 15kgf(147.1N) 30kgf(294.2N) 45kgf(441.3N) |

| Rocket Ruler | HR15N, HR30N, HR45N, HR15T, HR30T, HR45T |

| Inspection standards | GB/T230.1, GB/T230.2 Chinese Standard, JJG112 Verification Regulations

GB/T2848, GB/T3773 original standard, EN10109, ASTM E18, ISO 6508 |

| Precision | 0.1HR |

| Dwell time(s) | 1-60 |

| Hardness reading method | 7 inch touch LCD screen |

| Maximum allowable height of test piece (mm) | 190 |

| Distance from indenter center to fuselage (mm) | 165 |

| Dimensions of Hardness Tester (mm) | 550×220×730 |

| power supply | 220V/50HZ |

| Instrument weight (kg) | 75 |

| Hardness test range | HR15N:70-94 HR30N:42-86 HR45N:20-77

HR15T:67-93 HR-30T:29-82 HR45T:10-72 |

Instrument standard configuration:

| No. | Name (specification) | Quantity |

| 1 | Diamond Rockwell indenter, φ1.5875mm cemented carbide indenter | 1 each |

| 2 | Daping test bench, Zhongping test bench, “V” type test bench | 1 each |

| 3 | HR30T | 1 |

| 4 | HR30N HR15N | 1 each |

| 5 | Fuse 2A | 2 |

| 6 | power cable | 1 |

| 7 | Weights A, B, C | 1 each |

| 8 | Dustproof plastic cover | 1 |

| 9 | Product Certificate of Conformity | 1 |

| 10 | Printer paper, | 1 |

| 11 | Instruction Manual | 1 |

MAECENAS IACULIS

Vestibulum curae torquent diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Valoraciones

No hay valoraciones aún.