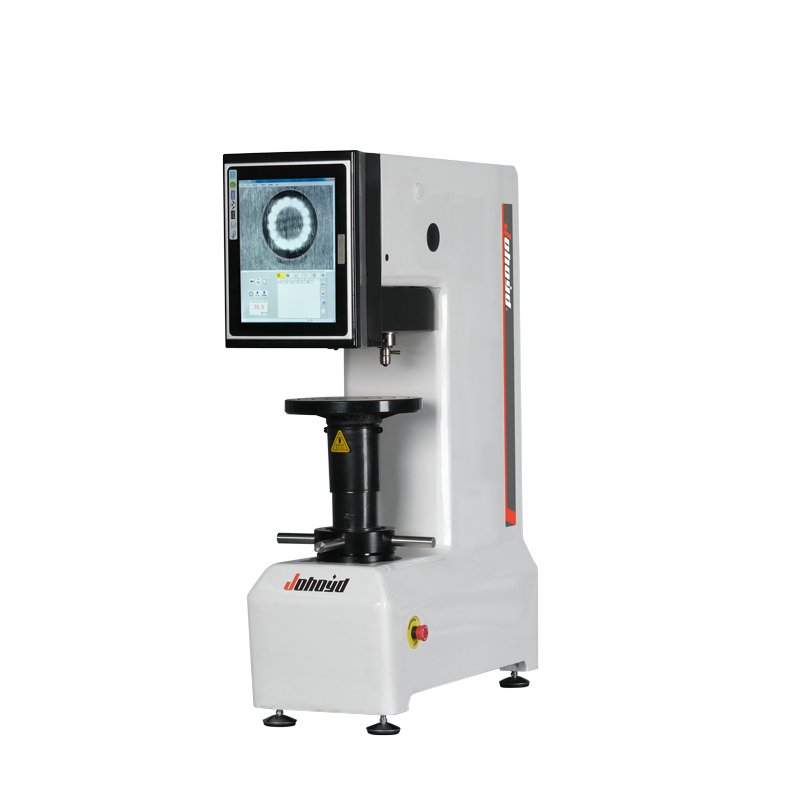

(HV-1000Z)Microdurómetro automático de torreta

The automatic turret type microhardness tester is a high-tech product of optical and mechanical integration. The hardness tester is novel in shape, has good reliability, operability and repeatability, and is an ideal product for testing microhardness. The machine uses C language programming, high-magnification optical measurement system and optical dual-channel structure, new technologies such as optoelectronics and photocouple sensing. Through key operation, the length of the measured indentation can be input on the key, the hardness value, the conversion scale, the test force, the test force holding time and the number of measurements can be displayed on the LCD screen.

Funciones y características principales:

- The optical system designed by senior optical engineers not only has clear images, but also can be used as a simple microscope. The brightness is adjustable, and it is visually comfortable. Long-time operation will not make you fatigued.

- The industrial display screen can directly display the hardness value, the conversion hardness, the test method, the test force, the retention time, the number of measurements, and the test process is intuitive and clear;

- Cast aluminum shell molding, stable structure won’t be easily deformed, pure white car paint high grade, anti-scratch ability, use for many years is still bright as new;

- Our company has its own R & D design, production and processing capabilities, our machine life to provide parts replacement and maintenance upgrades

- HV-1000Z model can be achieved: observation – test – measurement of the position switch by the automatic turret

Application:

- Hierro y acero, metales no ferrosos, láminas metálicas, aleaciones duras, chapas metálicas, microestructuras

- Capas de carburación, nitruración y descarburación, capas de endurecimiento superficial, chapado, revestimientos

- Glass, wafers, ceramic materials

Parámetros técnicos:

| Nombre del parámetro | Datos de los parámetros |

| Escala de microdureza | HV0.01,HV0.025,HV0.05,HV0.1,HV0.2,HV0.3,HV0.5,HV1 |

| Mostrar | Tiempo de mantenimiento (segundos), valor de dureza |

| Fuerza de ensayo (gf) | 10,25,50,100,200,300,500,1000 |

| Control de carga | Automático (carga/retención/desinstalación) |

| Tiempo de retención de la fuerza de ensayo (s) | 5 ~ 60 |

| Selección de la fuerza de ensayo | Botón selector externo, la fuerza de prueba se muestra automáticamente en la pantalla LCD |

| Aumento objetivo | 10×, 40× |

| Canal óptico | Canales de luz dobles (oculares y canales de cámara CCD) |

| Sistema óptico | 1. Manual micrometer eyepiece (10 times); total magnification (μm): 100× (observation), 400× (measurement);

2. The manual micrometer eyepiece can be changed 15 times, the total magnification is: 150X (observation), 600X (measurement) 3. Rango de medición (μm): 200; 4. Resolución (μm): 0.25 |

| Rango de medición de la dureza | (5-3000) HV |

| Plataforma de pruebas XY | Tamaño (mm): 100×100 Rango de recorrido (mm): 25×25 Lectura mínima (mm): 0.01 |

| Altura máxima de la probeta (mm) | 110 |

| Anchura máxima de la probeta (mm) | 85 (distancia de la línea central del penetrador a la pared) |

| Tensión | AC220V/50HZ |

| Peso (kg) | 35 |

| Dimensiones | (540×200×530)mm |

Configuración estándar:

| 1. Host ( Micro Vickers indenter x1, 10x objective x1, 40x objective x1) | 2. Test platform, weight, microscope accessory box; |

| 3.Pesas x6 | 4.Barra de pesas x1 |

| 5.Mesa transversal x1 | 6.Mesa de sujeción de chapas x1 |

| 7.Mesa de sujeción de boca plana x1 | 8.Mesa de sujeción del filamento x1 |

| 9.Nivel metro x1 | 10.Destornillador x2 |

| 11.Tornillos de ajuste horizontal x4 | 12.Cable de alimentación externo x1 |

| 13,10× Micrómetro digital Oculares x1 | 14.Micro Vickers hardness block x2 (HV1, HV0.2 x1 for each ) |

| 15.Fusibles (1 A) x2 | 16.Certificación del producto x1 |

| 17.Manual de instrucciones del producto x1 | 18.Funda antipolvo x1 |

Nota:

- Optional side-sway lifting system makes the lifting system more stable and accurate

- Software de medición de medidor de dureza opcional, eliminar el error humano, la operación de la computadora, mejorar la eficiencia, la precisión es más precisa.

- Cooperation institutions: Nanjing University of Science and Technology, Hefei University of Technology, Harbin Institute of Technology, Wuxi Jiangnan University, Guilin University of Electronic Technology, etc.

MAECENAS IACULIS

Vestibulum curae torquent diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.Condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Valoraciones

No hay valoraciones aún.