Hardness Tester Distributor Complete Guide 32 Smart Insights to Choose a Reliable Partner

Outline for the Article on Hardness Tester Distributor

| Topic Area | Detailed Coverage with LSI Keywords |

|---|---|

| Introduction to Hardness Tester Distributor | hardness tester supplier |

| What Is a Hardness Tester Distributor | equipment distribution |

| Role of Distributors in Hardness Testing Industry | value-added services |

| Difference Between Manufacturer and Distributor | supply chain |

| Types of Hardness Testers Distributed | Rockwell, Brinell, Vickers |

| Manual Hardness Tester Distribution | entry-level testers |

| Digital Hardness Tester Distribution | electronic hardness testers |

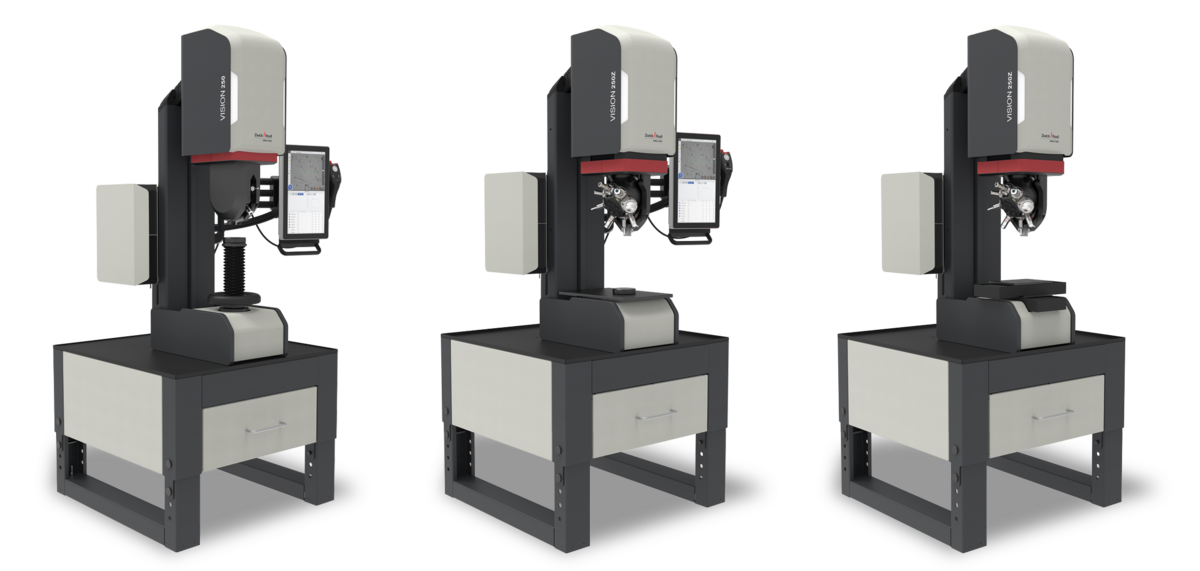

| Automatic Hardness Tester Distribution | automated testing systems |

| Portable Hardness Tester Distribution | on-site testing tools |

| Laboratory Hardness Tester Distribution | precision instruments |

| Industrial Hardness Tester Distribution | production solutions |

| Distributor Inventory and Stock Management | availability |

| Local vs Global Hardness Tester Distributors | regional support |

| Distributor Role in Quality Control Solutions | inspection support |

| Industry Applications Supported by Distributors | automotive, aerospace |

| Distributor Technical Expertise | application guidance |

| Pre-Sales Consultation Services | solution matching |

| Demonstration and Trial Support | evaluation assistance |

| Installation and Commissioning Services | startup support |

| Calibration and Maintenance Support | accuracy assurance |

| Spare Parts and Consumables Supply | long-term operation |

| Software and Digital Integration Support | data solutions |

| Compliance and Standards Support | ASTM, ISO |

| Distributor Pricing and Value | cost efficiency |

| Lead Time and Logistics Capabilities | delivery reliability |

| Training and User Support | operator confidence |

| After-Sales Service Importance | customer satisfaction |

| Choosing a Reliable Hardness Tester Distributor | selection guide |

| Common Mistakes When Selecting a Distributor | buyer errors |

| Distributor vs Online Marketplace | risk comparison |

| Johoyd Authorized Distribution Network | brand presence |

| Future Trends in Hardness Tester Distribution | digital sales |

| Buyer Checklist | decision tool |

| Preguntas frecuentes | common questions |

| Conclusion | summary |

Introduction

Selecting the right hardness tester distributor is just as important as choosing the hardness testing machine itself. Distributors act as the bridge between manufacturers and end users, ensuring that testing equipment is delivered, installed, supported, and maintained correctly. A reliable distributor adds technical expertise, local service capability, and long-term support that go far beyond simple product supply.

This article explains the role of hardness tester distributors, the services they provide, how they differ from manufacturers, and how buyers can choose a trustworthy distribution partner for long-term success.

Hardness Tester Distributor

A hardness tester distributor supplies hardness testing machines and related accessories while offering technical support, logistics, and after-sales services.

Distribution defines accessibility.

What Is a Hardness Tester Distributor

A hardness tester distributor is a company authorized to sell and support hardness testing equipment from one or more manufacturers.

Authorization ensures credibility.

Role of Distributors in Hardness Testing Industry

Distributors ensure equipment availability, provide application guidance, and support customers throughout the product lifecycle.

Support enhances value.

Difference Between Manufacturer and Distributor

Manufacturers design and produce hardness testers, while distributors focus on sales, service, and customer support.

Roles complement each other.

Types of Hardness Testers Distributed

Distributors supply Rockwell, Brinell, Vickers, Shore, microhardness, and portable hardness testers.

Product range meets diverse needs.

Manual Hardness Tester Distribution

Manual hardness testers are distributed for basic testing needs and budget-conscious users.

Simple solutions remain important.

Digital Hardness Tester Distribution

Digital hardness testers are popular due to accuracy and ease of use.

Digital demand continues to grow.

Automatic Hardness Tester Distribution

Automatic hardness testers are distributed for high-volume production environments.

Automation supports efficiency.

Portable Hardness Tester Distribution

Portable hardness testers enable on-site testing of large or fixed components.

Mobility adds flexibility.

Laboratory Hardness Tester Distribution

Laboratory testers emphasize precision and repeatability.

Distributors support research needs.

Industrial Hardness Tester Distribution

Industrial hardness testers are designed for harsh production environments.

Durability ensures uptime.

Distributor Inventory and Stock Management

Strong distributors maintain inventory to reduce lead times and support urgent needs.

Availability matters.

Local vs Global Hardness Tester Distributors

Local distributors provide fast service, while global distributors support multinational operations.

Coverage defines reach.

Distributor Role in Quality Control Solutions

Distributors help integrate hardness testers into quality control systems.

Integration improves compliance.

Industry Applications Supported by Distributors

Distributors serve automotive, aerospace, manufacturing, energy, and research sectors.

Industry knowledge adds value.

Distributor Technical Expertise

Experienced distributors provide application-specific advice and troubleshooting.

Expertise reduces risk.

Pre-Sales Consultation Services

Distributors help customers select the right hardness tester for their needs.

Correct selection saves cost.

Demonstration and Trial Support

Product demonstrations allow users to evaluate performance before purchase.

Trials build confidence.

Installation and Commissioning Services

Professional installation ensures correct setup and operation.

Proper start prevents issues.

Calibration and Maintenance Support

Distributors often provide calibration and maintenance services.

Accuracy must be maintained.

Spare Parts and Consumables Supply

Reliable distributors supply indenters, test blocks, and consumables.

Parts availability ensures continuity.

Software and Digital Integration Support

Distributors assist with software installation and data integration.

Digital support enhances usability.

Compliance and Standards Support

Distributors ensure equipment meets ASTM and ISO requirements.

Standards ensure acceptance.

Distributor Pricing and Value

Good distributors balance competitive pricing with strong service.

Value exceeds price.

Lead Time and Logistics Capabilities

Efficient logistics ensure on-time delivery and reduced downtime.

Timing matters.

Training and User Support

Training services improve operator confidence and testing accuracy.

Knowledge empowers users.

After-Sales Service Importance

After-sales service defines long-term satisfaction and reliability.

Service builds trust.

Choosing a Reliable Hardness Tester Distributor

Selection should consider authorization, experience, service capability, and references.

Careful choice prevents problems.

Common Mistakes When Selecting a Distributor

Mistakes include choosing based only on price or ignoring service quality.

Shortcuts cost more later.

Distributor vs Online Marketplace

Online marketplaces may lack technical support and service accountability.

Professional distributors reduce risk.

Johoyd Authorized Distribution Network

A trusted hardness tester distributor network ensures reliable access to quality equipment. Johoyd, through https://hardnesstests.com, works with professional distributors worldwide to provide Rockwell, Brinell, Vickers, digital, portable, and automatic hardness testers, supported by technical expertise, calibration services, and responsive after-sales support.

Future Trends in Hardness Tester Distribution

Future trends include digital sales platforms, remote diagnostics, and integrated service models.

Distribution continues to evolve.

Buyer Checklist

- Verify distributor authorization

- Evaluate technical expertise

- Check service and calibration capability

- Confirm inventory and lead times

- Assess training and after-sales support

Frequently Asked Questions

What does a hardness tester distributor do?

They supply and support hardness testing equipment.

Is a distributor different from a manufacturer?

Yes, distributors focus on sales and service.

Why choose an authorized distributor?

Authorization ensures genuine products and support.

Do distributors provide calibration services?

Many professional distributors do.

Can distributors help choose the right tester?

Yes, application guidance is a key service.

Is local distributor support important?

Local support reduces downtime.

Conclusion

A reliable hardness tester distributor plays a critical role in ensuring accurate, compliant, and efficient hardness testing operations. From equipment selection and installation to calibration and long-term support, distributors add value far beyond product delivery.

By working with professional distributors connected to Johoyd through hardnesstests.com, customers gain access to high-quality hardness testing solutions backed by technical expertise and dependable service. Choosing the right distributor today ensures confidence, productivity, and long-term success.

Suggested Internal Links

- Hardness Tester Manufacturer

- Hardness Tester Buyer’s Guide

Suggested Outbound Links

- ASTM Hardness Testing Standards

- ISO Hardness Measurement Guidelines