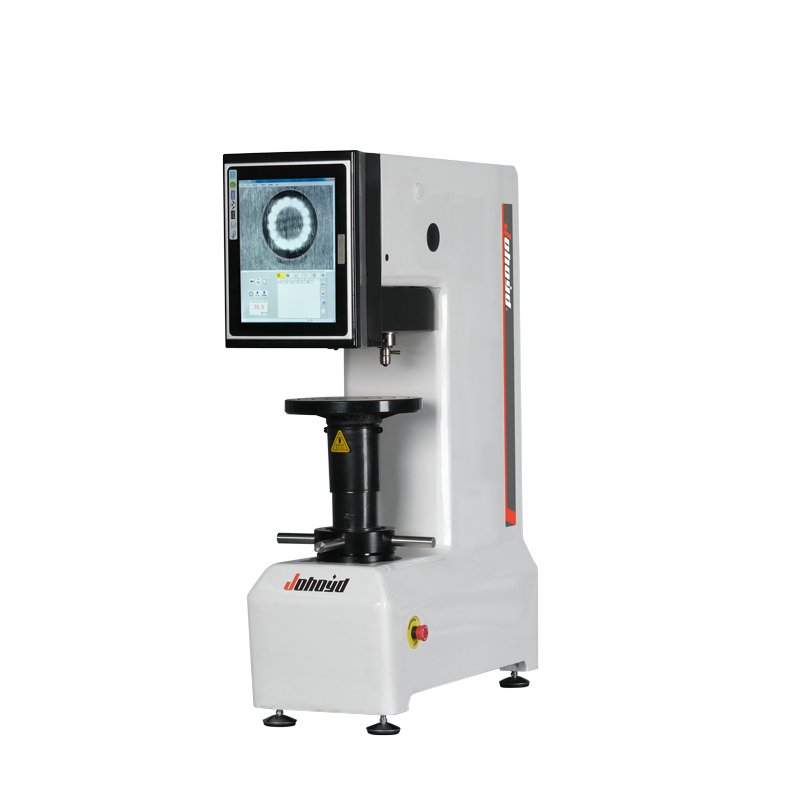

(PCHBST-3000Z )Visuelles digitales Brinell-Härteprüfgerät mit Touchscreen

PCHBST-3000Z Visual Touch Screen Digital Brinell Hardness Tester

The PCHBST-3000Z combines precision, automation, and ease of use for efficient hardness testing. Featuring visual indentation display and automatic hardness measurement, it allows real-time monitoring through a touch tablet or PC, with automatic data saving and report generation.

Equipped with photoelectric sensor technology, high-performance stepper motor, and LED optical measurement, the tester ensures accurate, stable, and fatigue-free operation. Users can easily select test parameters, monitor results, and perform multi-unit conversions with just a tap. The system supports automatic loading, holding, unloading, and compensation, and includes an emergency stop for safety compliance (EU CE standard).

With a durable, cast shell and scratch-resistant automotive paint finish, it operates reliably in demanding environments. Its wide testing range covers metals with large crystal grains, including cast iron, steel, non-ferrous metals, and softer metals like aluminum, lead, and tin, as well as certain hard plastics and bakelite.

Industrial tablet computer integration, support USB expansion

Visual display of indentation and automatic hardness measurement

Automatically generate WORD report to meet the needs of test personnel

PCHBS-3000Z Visual digital Brinell hardness tester can be easily measured by operating a touch tablet computer! And all the parameters required for the test can be directly selected, modified and analyzed on the computer. The PC terminal is connected with the hardness tester through communication protocol to control the mechanical moving parts of the hardness tester. It can realize: automatic multi-function tower position, automatic identification of objective lens and indenter, automatic loading, automatic load keeping, automatic unloading, and light brightness. By linking the built-in CCD measurement and acquisition system, clear indentation image dynamics can be displayed on the PC in real time, and the indentation can also be directly locked to automatically measure the hardness value, automatically save the test data, and generate a report. The operation is very simple and fast, eliminating man-made measurement errors.. With tablet computer as the platform, more application functions can be expanded through the Internet, and external displays, printers and other devices can also be connected.

The hardness tester’s machine software system adopts computer intelligent programming, uses photoelectric sensor technology, and independently selects test conditions. The test method, upper and lower limit range can be displayed on the 5.6-inch touch multifunctional display screen, and the indentation length, hardness value, and conversion value can be measured , Test force, hold time, number of measurements, and can enter year, month, date, test results and data processing, etc., and can output measurement data through a built-in printer or connect to a computer through a data interface. The optical system adopts high-magnification LED optical measurement, the image clarity is high, the brightness is adjustable, and the long-term operation is not suitable for fatigue. The hardware system uses advanced electronic sensor loading technology. Through the closed-loop control system, the CPU controls the sensor to collect signals. The stepper motor automatically loads and unloads the test force, and can automatically compensate the test force to ensure more accurate force values and better indications. Stablize. At the same time, it is equipped with an emergency stop device, which meets the EU CE safety standards. With humanized operability, more reliable stability and safety.

Main functions and features: |

- This machine has the characteristics of high precision, high repeatability and stability, simple operation, convenient and practical, and high cost performance;

- The system automatically prompts to measure the minimum thickness of the product;

- Possesses level 10 test capability, and can test a wider range;

- Equipped with digital display micrometer eyepiece and accurate data calculation system, the hardness value can be directly displayed with just one tap;

- Equipped with a built-in printer to output the measurement data or connect to the computer to transmit the measurement data of the host to the computer for editing and saving;

- Equipped with high-performance stepper motor to automatically load and unload the test force, the noise generated during the test is smaller

- Using photoelectric sensor technology and microcomputer control system, it can automatically compensate, and the test results are accurate and stable;

- Automatically enter the indentation diameter and directly display the hardness value, which can realize dual display of any hardness unit, avoiding the cumbersome check-up table;

- Self-contained design of high-magnification LED optical measurement, high image clarity, adjustable brightness, long-term operation is not suitable for fatigue;

- The shell is cast at one time, the structure is stable and does not deform, and it can work in a relatively harsh environment;

- The surface is treated with the car paint process, which has strong scratching ability and is still as bright as new after years of use;

Main purpose and scope of use:

- It is suitable for the hardness test of metal materials with large crystal grains, which can reflect the comprehensive performance of the material;

- Cast iron, steel, non-ferrous metals, especially suitable for softer metals, such as pure aluminum, lead, tin, etc.

- It can be used to measure the hardness of some non-metallic materials, such as hard plastic, bakelite, etc.

Technical parameter: |

| Product model | PCHBS-3000Z |

| Brinell Ruler | HBW2.5/62.5 HBW2.5/187.5 HBW5/62.5 HBW5/125 HBW5/250 HBW5/750 HBW10/100、 HBW10/250 HBW10/500 HBW10/1000 HBW10/1500 HBW10/3000 |

| Test force | 62.5kgf(612.9N)100kgf(980.7N)125kgf(1226N)187.5kgf(1839N)250kgf(2452N)500kgf(4903N)750kgf(7355N)1000kgf(8907N)1500kgf(14710N)3000kgf(29420N) |

| Loading control | Automatic (loading/holding/unloading) |

| Maximum height of specimen | 220mm |

| Indenter-outer wall distance | 135mm |

| Indenter-upper wall distance | 55mm(The distance from the indenter to the upper machine wall can be increased by customizing the indenter ) |

| Smallest unit of measurement | 0.125um |

| Dwell time | 0~60s |

| Hardness test range | 8~650HBW |

| Turret | Automatic turret |

| Hardness reading | PCAutomatic hardness measurement |

| Error correction | The system calibrates the hardness at any time |

| Qualified judgment | The qualified range can be set, and the machine automatically reminds whether it is qualified |

| Total magnification | 20X |

| Executive standard | EN ISO 6506, , ASTM E-10-08, GB/T231.2,JJG150 -2005 |

| Data output | The computer saves the test data directly |

| power supply | AC220+5%,50~60Hz |

| Overall size (mm) | 520*210*745mm |

| Host weight | About 125kg |

MAECENAS IACULIS

Vestibulum curae torquent diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Rezensionen

Es gibt noch keine Rezensionen.