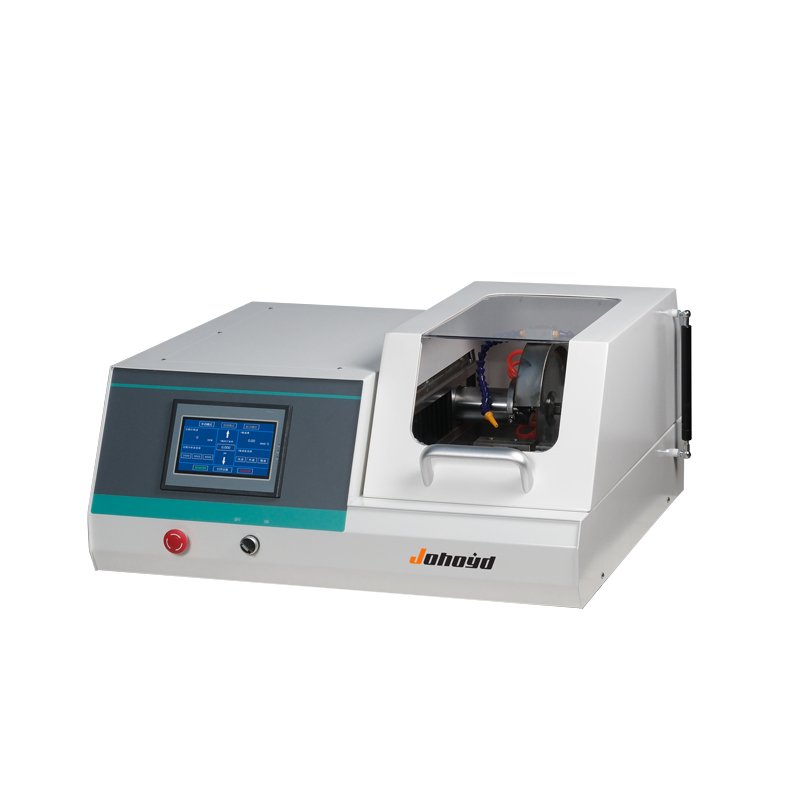

HMP-1A Vollautomatische Schleif- und Poliermaschine für metallographische Proben

HMP-1A is a single-disk fully automatic grinding and polishing machine that integrates pre-grinding, grinding and polishing. It uses single-chip microcomputer technology to control through a touch screen. The grinding and polishing disc is driven by a DC brushless motor and a V-belt. The grinding head is driven by a stepper motor and a synchronous belt. It has the characteristics of stable rotation, low noise, long life, safety and reliability. It can adjust the speed of the grinding head and the grinding and polishing disc according to user needs, set the pressure and sample preparation time by itself to meet different needs. It has its own lighting system for easy placement of samples. It has its own cooling device to cool the sample during grinding to prevent the metallographic structure from being damaged due to overheating of the sample. It is an ideal choice for metallographic sample preparation equipment in factories, scientific research institutions and laboratories of colleges and universities.

Product advantages:

- The base is made of aluminum alloy material, which is lightweight, has good shock absorption and corrosion resistance.

- The shell is made of high-end ABS, which is novel in appearance, high-end and classy.

- Touch screen display control, clear and intuitive interface, easy to operate.

- It can be timed, fixed speed and fixed pressure.

- The built-in nozzle sump is automatically cleaned.

- Infinite speed regulation or four-speed speed regulation, convenient and fast.

- It can be started in single action or linkage as needed.

- More than 10 sets of grinding and polishing process formulas can be stored for quick call.

- The magnetic disk design supports fast disk change, and it is more convenient and quick to change sandpaper and polishing fabric.

- The free rotation design of the sample clamping plate, combined with the inner lighting system, is convenient for taking and placing samples.

- The grinding head adopts electromagnetic clutch automatic locking, which is convenient and fast. (Optional)

- The whole machine adopts DC brushless and stepper motors, which rotate smoothly, have low noise and long life.

Technische Parameter:

| Name | Specifications |

| Grinding disc diameter | Standard φ254mm |

| Grinding disc speed | 100-1000r/min (stepless speed regulation) Four-speed speed regulation 300 500 800 1000r/min |

| Grinding head speed | 0—120r/min |

| Grinding disc rotation direction | Two-way forward and reverse |

| Grinding disc motor power | 1.1KW |

| Grinding head rotation direction | Clockwise |

| Grinding head motor power | 0.2KW |

| Grinding head locking method | Manual (optional automatic) |

| Timing adjustable time | 0-99min |

| Pressure method | Single-point pneumatic pressurization |

| Pressure adjustment method | Mechanical pressure regulation |

| Pressure range | 0-0.3Mpa (commonly used 0.05-0.3Mpa) |

| Specimen clamping specifications | Standard Ф30 (others can be customized) |

| Number of specimen clamping | 6 |

| Power supply | Spannung: 220V Frequenz: 50HZ |

| Total power | 1.8KW |

| Overall dimensions | 500X770X700mm |

| Wooden box dimensions | 560X820X800 |

| Gewicht | 80Kg |

Shipping accessories:

| Name | quantity | Unit | Notes |

| Grinding disc Φ254 | 1 | each | Installed on the device |

| Magnetic disc | 1 | each | Installed on the device |

| Water retaining ring | 1 | each | Installed on the device |

| Anti-stick disc | 2 | each | Φ250mm |

| 400 mesh adhesive sandpaper | 4 | piece | Φ250mm |

| 800 mesh adhesive sandpaper | 4 | piece | Φ250mm |

| 1200 mesh adhesive sandpaper | 4 | piece | Φ250mm |

| Adhesive polishing cloth | 4 | piece | Φ250mm |

| Water inlet pipe | 1 | root | 6-point interface |

| Water outlet pipe | 1 | root | Φ32 |

| Technical documents | 1 copy of product manual 1 copy of product certificate | ||

MAECENAS IACULIS

Vestibulum curae torquent diam commodo parturient penatibus nunc dui adipiscing convallis bulum parturient suspendisse parturient a.Parturient in parturient scelerisque nibh lectus quam a natoque adipiscing a vestibulum hendrerit et pharetra fames nunc natoque dui.

ADIPISCING CONVALLIS BULUM

- Vestibulum penatibus nunc dui adipiscing convallis bulum parturient suspendisse.

- Abitur parturient praesent lectus quam a natoque adipiscing a vestibulum hendre.

- Diam parturient dictumst parturient scelerisque nibh lectus.

Scelerisque adipiscing bibendum sem vestibulum et in a a purus lectus faucibus lobortis tincidunt purus lectus nisl class eros.condimentum a et ullamcorper dictumst mus et tristique elementum nam inceptos hac parturient scelerisque vestibulum amet elit ut volutpat.

Rezensionen

Es gibt noch keine Rezensionen.